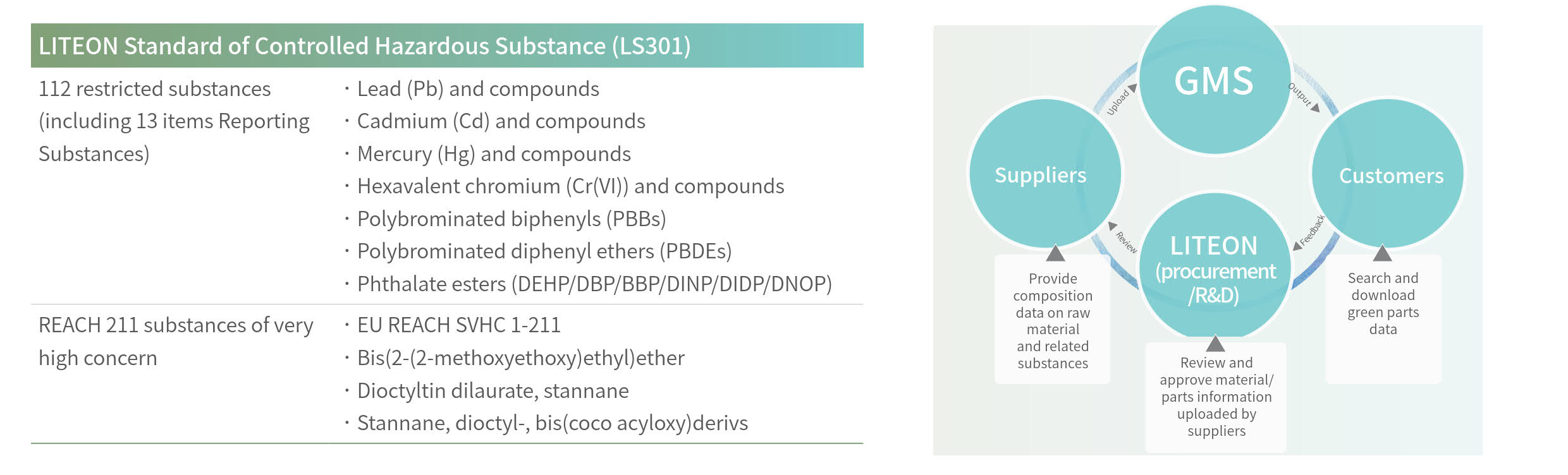

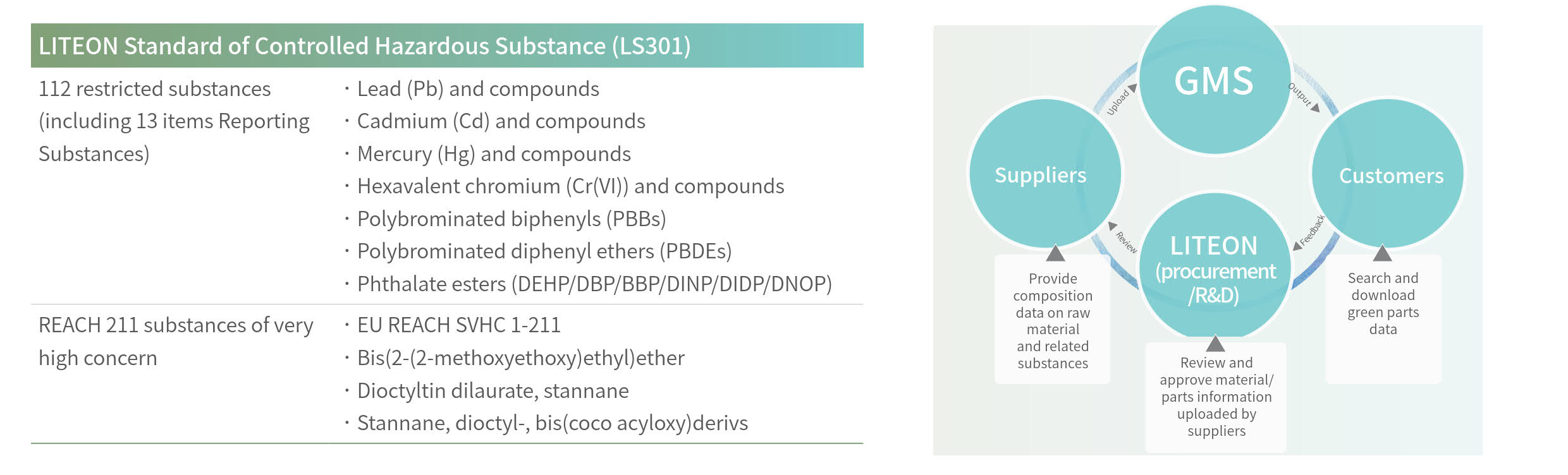

Environment-Related Substances Management

In 2010, LITEON implemented the LITEON LS301 standards by following the IECQ QC

080000 system and taking into account the latest trends in other countries, regulations,

and customer needs. The LS301 standards apply to all products. The LS301 standards are

revised from time to time after calibration with different versions adopted by different

business units. The total number of restricted substances reached 323 in 2020.

The in-house Green product Management System (GMS) works with the "restricted

substances management" and " design development management" procedures already

in place as well as the LS301 standards for hazardous substance management. LITEON

also requires that suppliers (including contractors) comply with the LITEON Guidelines

for Green Procurement and submit the Supplier Statement of Restricted Substances

Compliance for material/part acknowledgment and internal control. Furthermore, LITEON

states explicitly in all procurement contracts the strict requirement for materials, parts,

or semi-finished goods to comply with or exceed RoHS, REACH, California Proposition 65,

and Montreal Protocol. With the implementation of green supply chain management, we

hope to achieve the goal of sourcing environmentally friendly materials, manufacturing

and providing to our customers low-toxicity and low-pollution products to minimize any

harmful impact they may have on the human body or the environment.

LITEON installs the Green product Management System (GMS) to effectively manage and

review compliance with the LS301 criterion for raw materials, parts, or semi-finished

goods provide by the suppliers. GMS combines material requirements, international

laws, international directives, customer policies, and supplier information. Suppliers file

product testing and analysis results for the system to determine automatically whether

they comply with the rules and directives. LITEON will summarize and analyze the data,

and check the degree of compliance with the LS301 standards. Furthermore, GMS not

only actively delivers information on green product management at LITEON to customers,

but also feeds environmental requirements or provisions for green products, such as ErP,

WEEE, and 3R, from customers into the management system to provide a basis for green

product design.

LITEON made a running change to replace materials, parts, and modules containing diisobutyl phthalate (DIBP). The substance ceased to be used in any of the products in January 2019.

Air Pollution Prevention

Volatile organic compounds (VOCs) emitted at LITEON come

mainly from organic solvents used during production, such as

soldering flux and isopropanol vapors. NOx and SOx emissions

from generators used for emergency or testing in the plants and

from hot water boilers in the living area are considered trace

amounts. LITEON manages VOC emissions through management

styles, procedure improvement, training, and regular third-party

inspection. In addition, LITEON started implementing stronger

outdoor air pollution emission controls on site in 2017.

Inspection data from the plants, actual factory conditions and

local environmental policies were considered in the design of

comprehensive and reasonable emission treatment systems

with two levels or more (e.g., precipitators, UV photocatalysis,

and activated carbon-based absorption). These systems were

built to fulfill a comprehensive purpose including removing

VOC pollutants, optimizing control, reducing consumption,

and ensuring safety. VOC emissions at LITEON are calculated

according to the test data of third-party environmental

compliance inspection reports and hours of operation. The total

emissions reported from LITEON's main manufacturing bases

worldwide were 36.3Note tons in 2021.

Note: Emission data includes Changzhou, Tianjin, Huizhou, Dongguan, Guangzhou and India in a total of 12 production sites

Environmental Sustainability ▸

言語を選択する