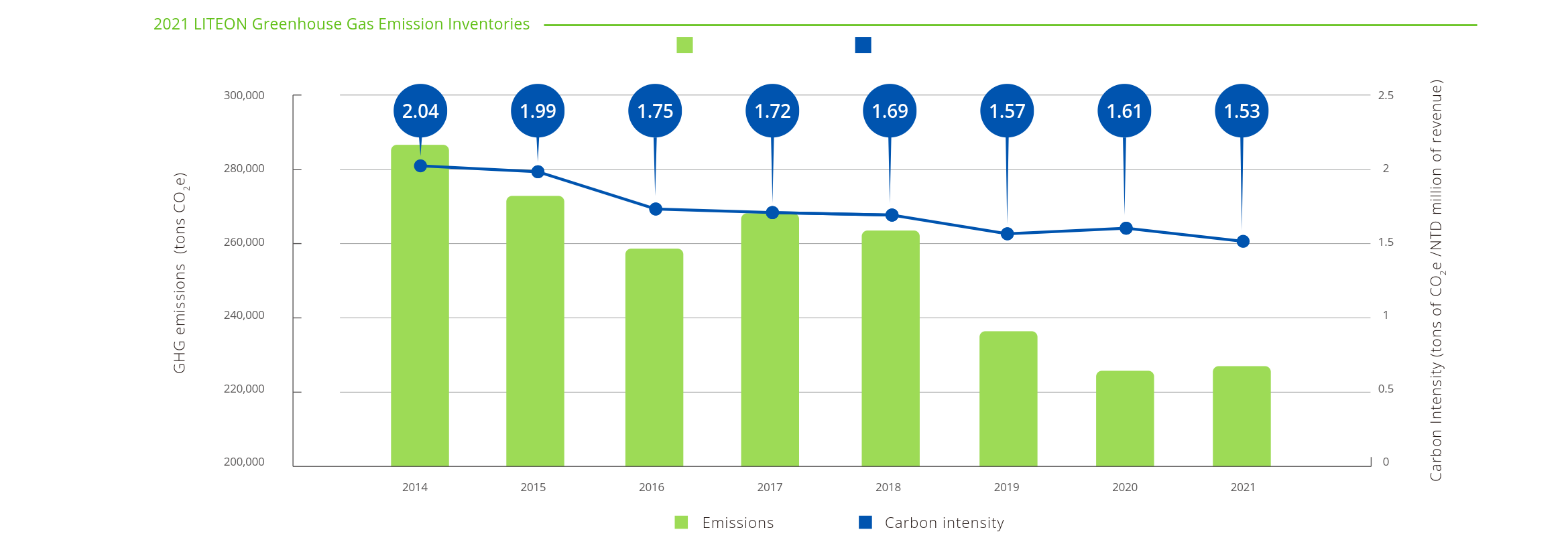

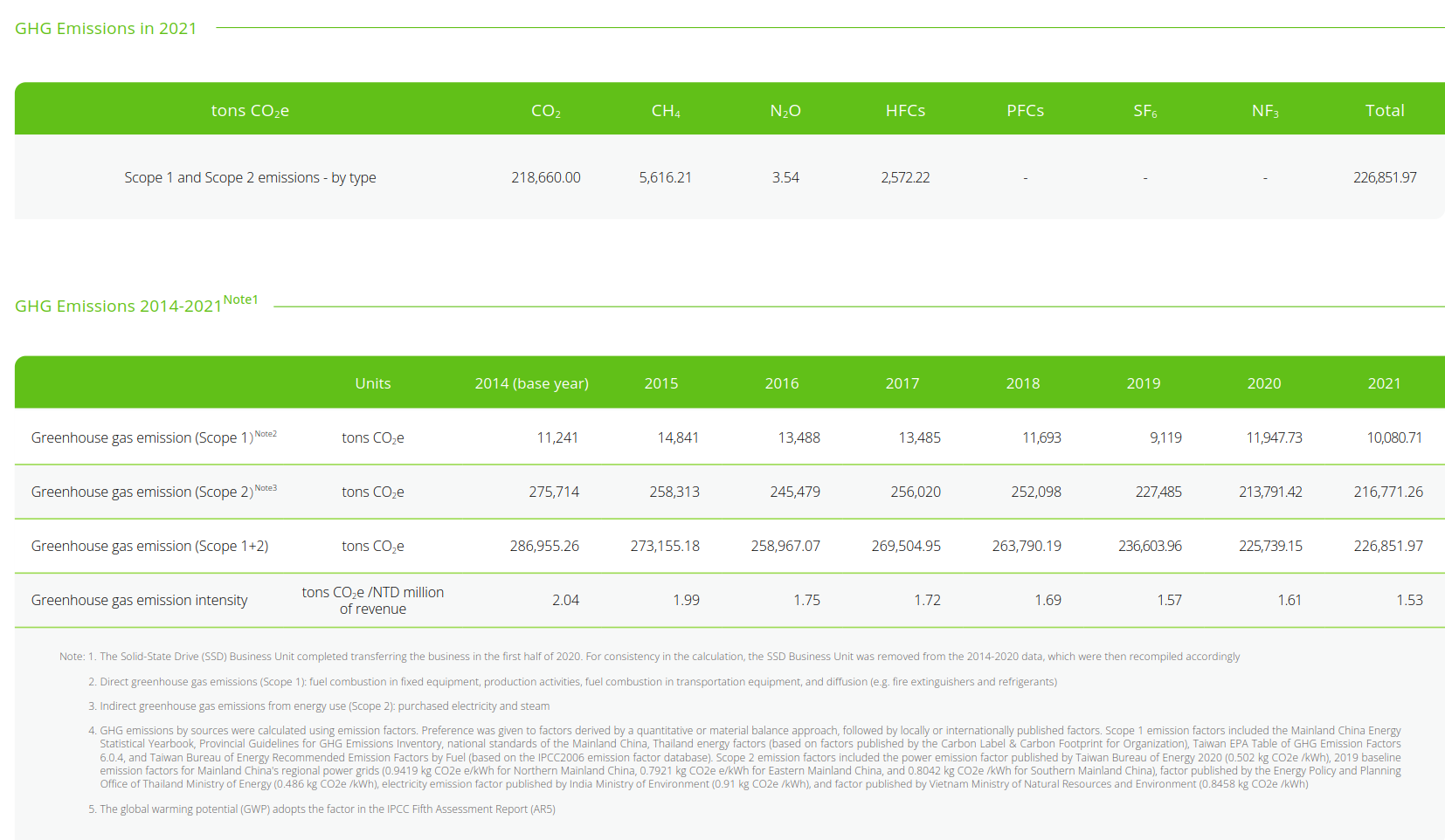

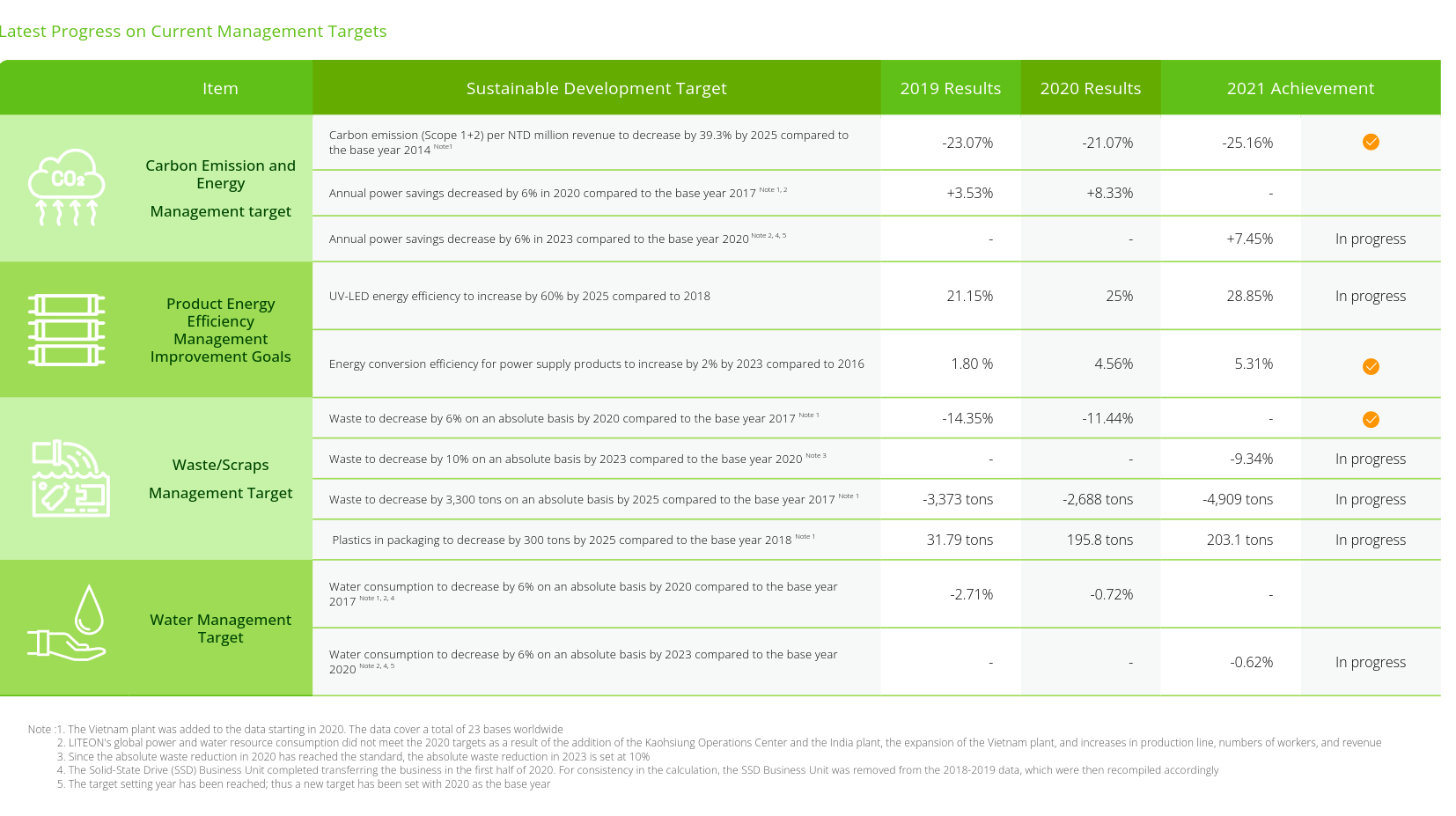

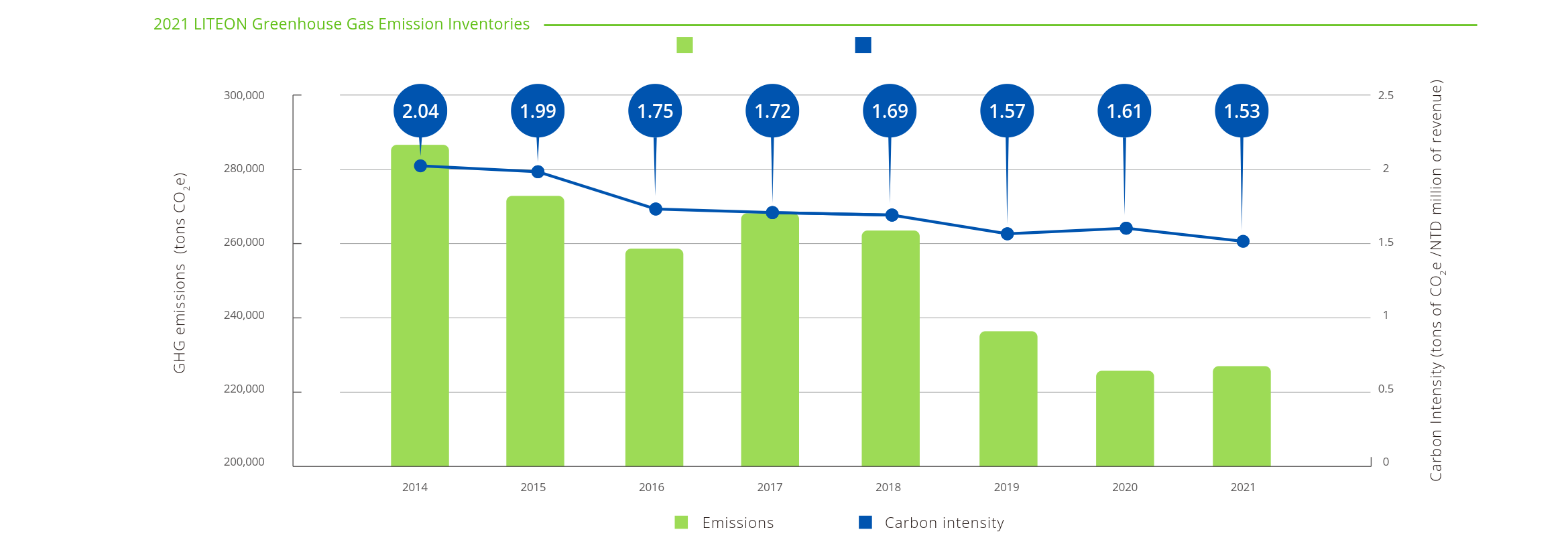

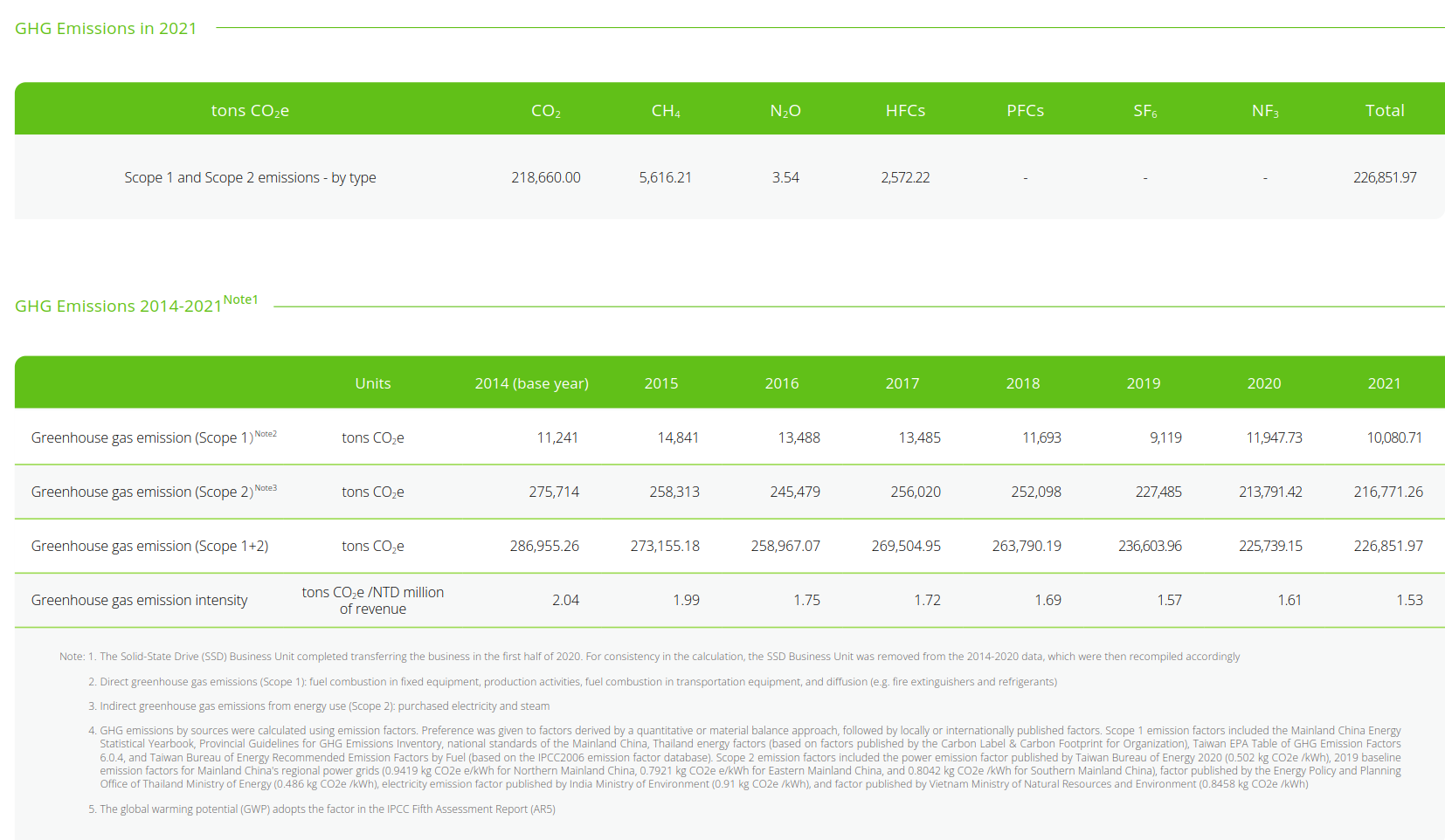

Greenhouse Gas Inventory (GHG Scope 1 and Scope 2)

According to the ISO 14064-1:2006 standard for GHG emissions inventory, in 2021, LITEON's direct GHG emissions (Scope 1) and indirect GHG emissions (Scope 2) were 226,851.97 tons CO2e market-based, an increase of 1,113 tons of CO2e compared to 2020 (up by 0.49%), and 60,103 tons of CO2e (down by 20.95%) less than the base year 2014. The carbon intensity was 1.53 tons CO2e/NTD

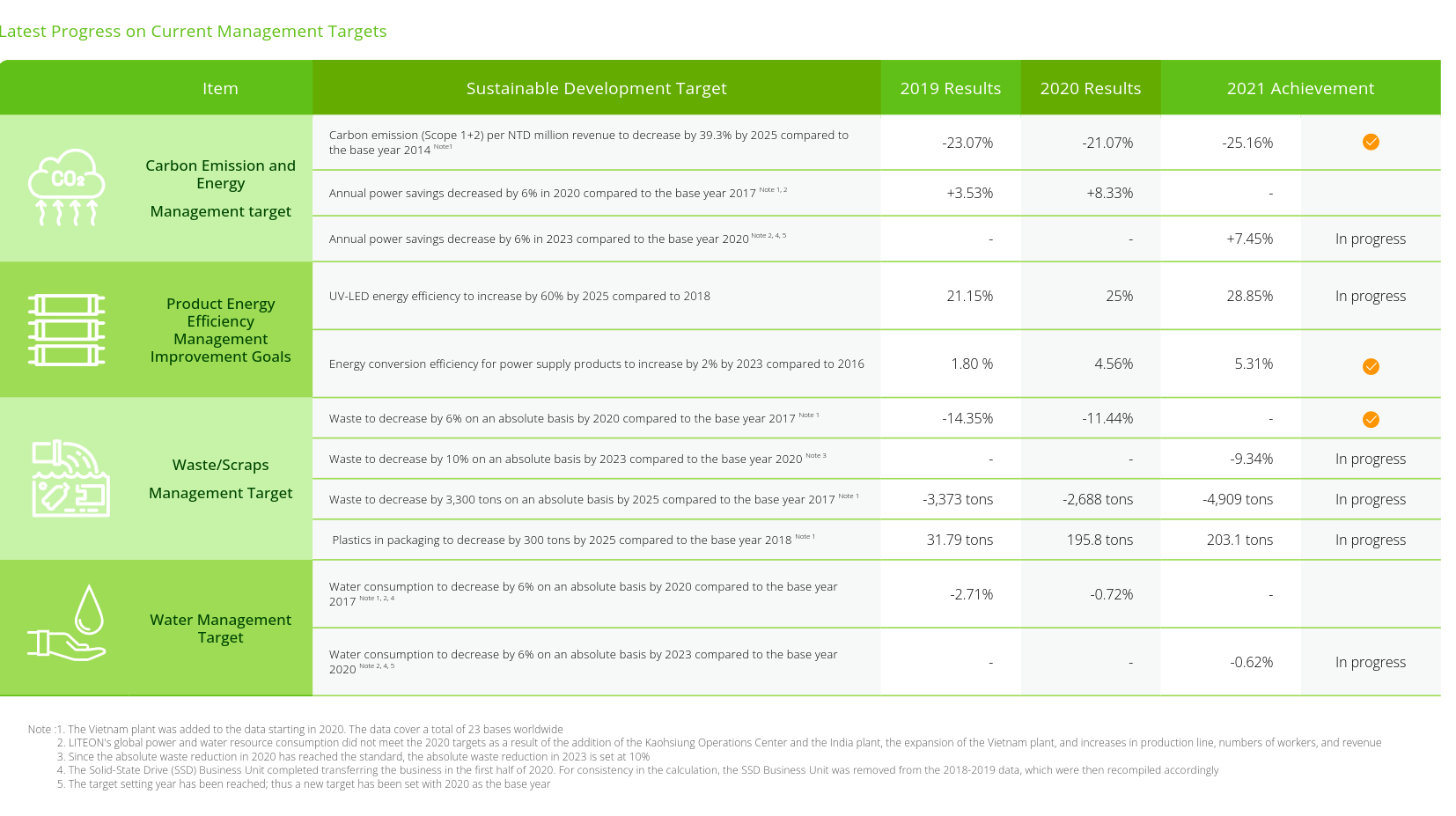

million of revenue, 5.35% lower than in 2020 and 25.16% lower than the base year 2014. The figures complied with the SBT reduction path target of 24.6% for 2021..

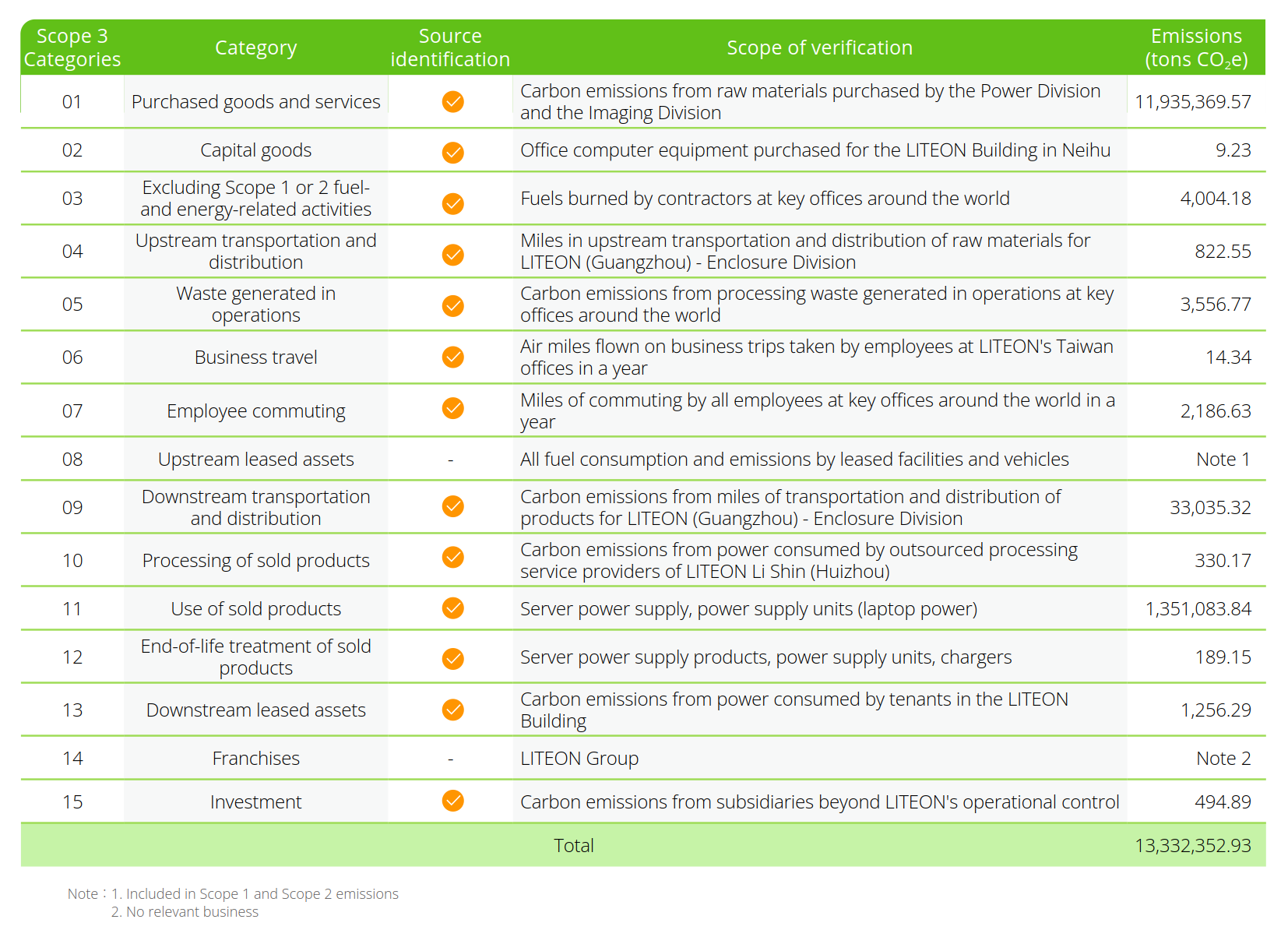

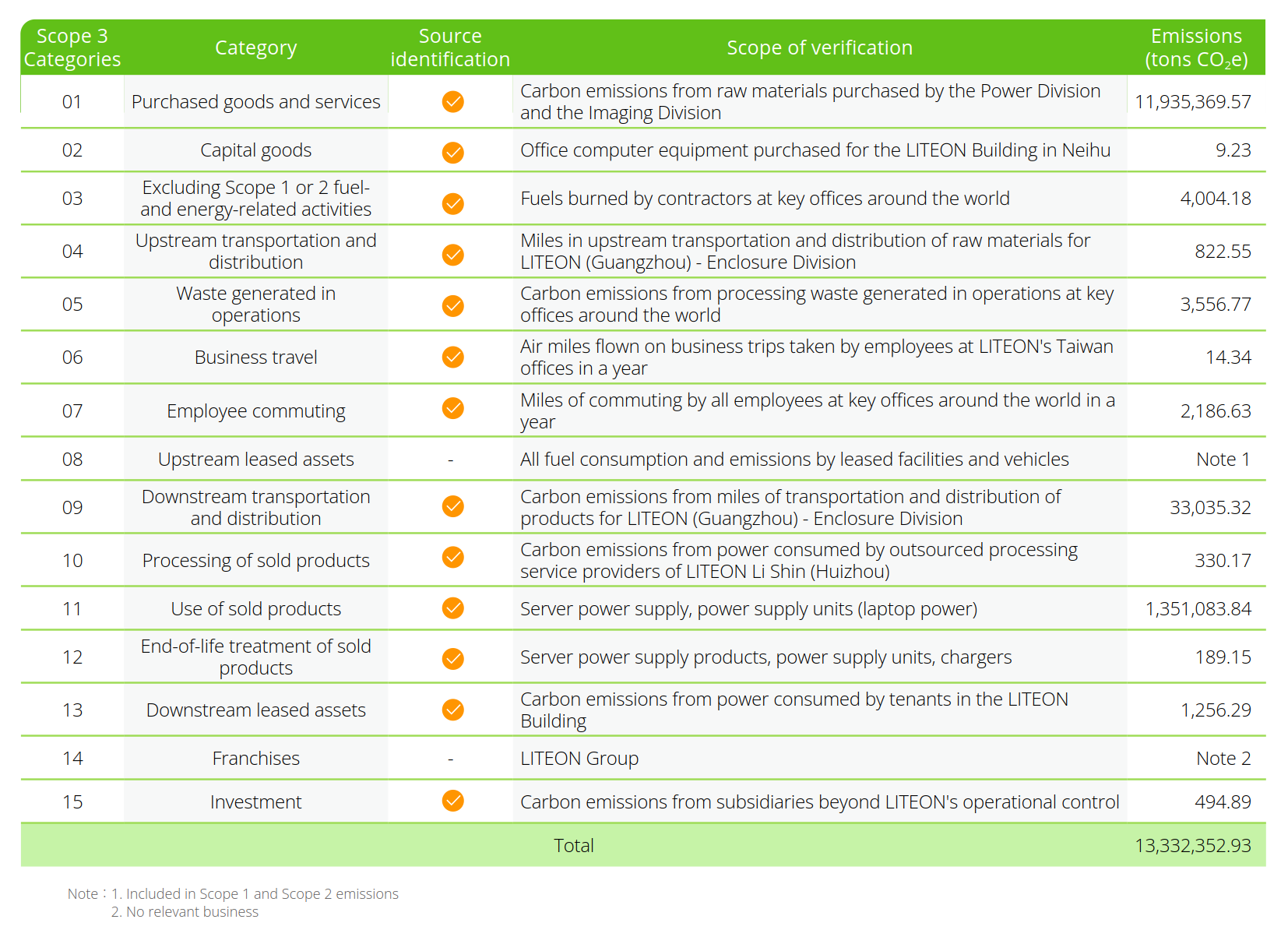

Greenhouse Gas Value Chain Inventory (GHG Scope 3)

To maximize the value of the LITEON value chain and to identify key factors to mitigating climate change, LITEON not only takes inventories of emissions from its own business activities, but has started performing full inventory-taking, verification, and disclosure of emissions from 15 categories in Scope 3 every year since 2018. The practice allows LITEON to follow emission hot spots along the value chain and extend carbon management to business partners on the value chain. In terms of Scope 3 emissions, LITEON sets 2018 as the base year, and aims to reduce cumulative value chain emissions (Scope 3) by 2 million tonnes by 2030. Meanwhile, the company continues to deploy green product design and other strategies and work with value chain partners to develop low carbon products and combat climate change and global warming together.

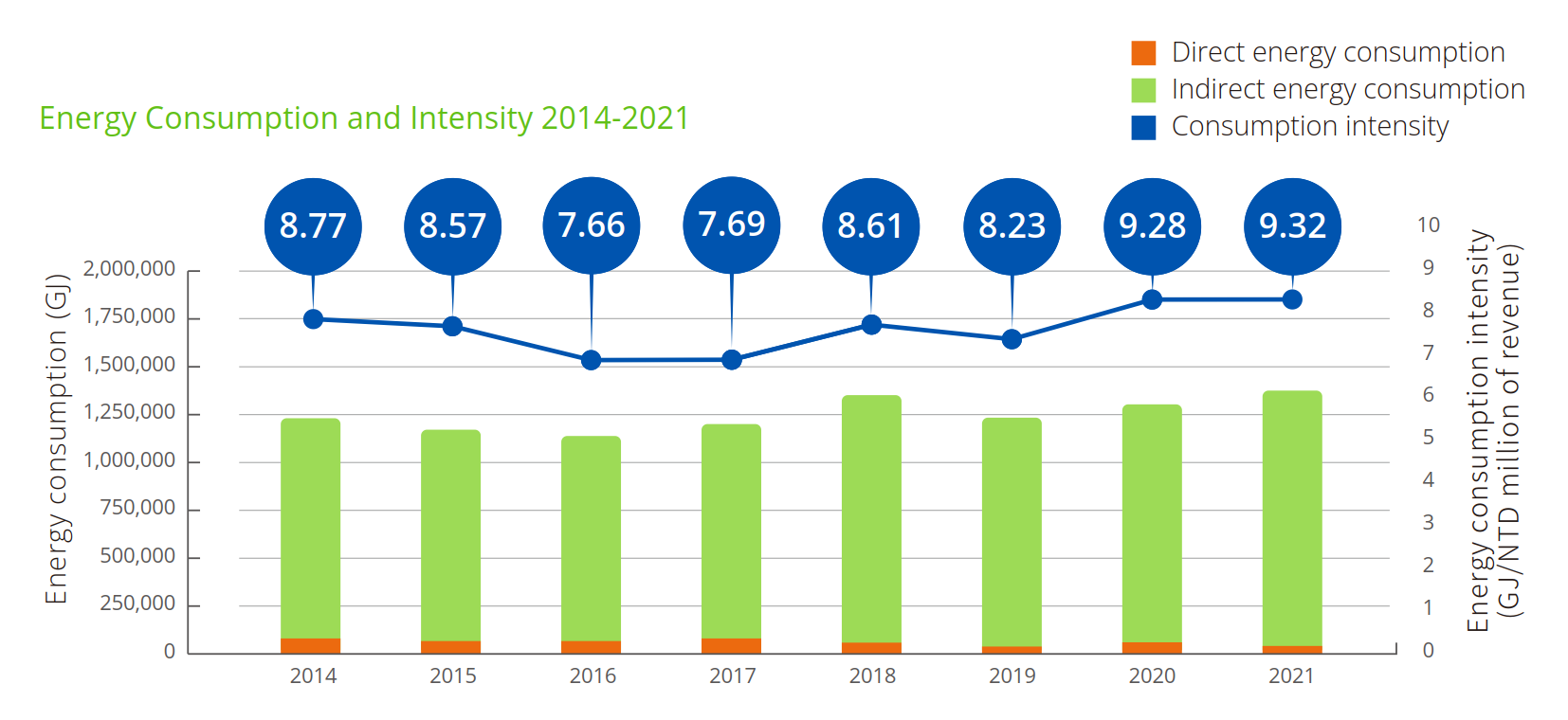

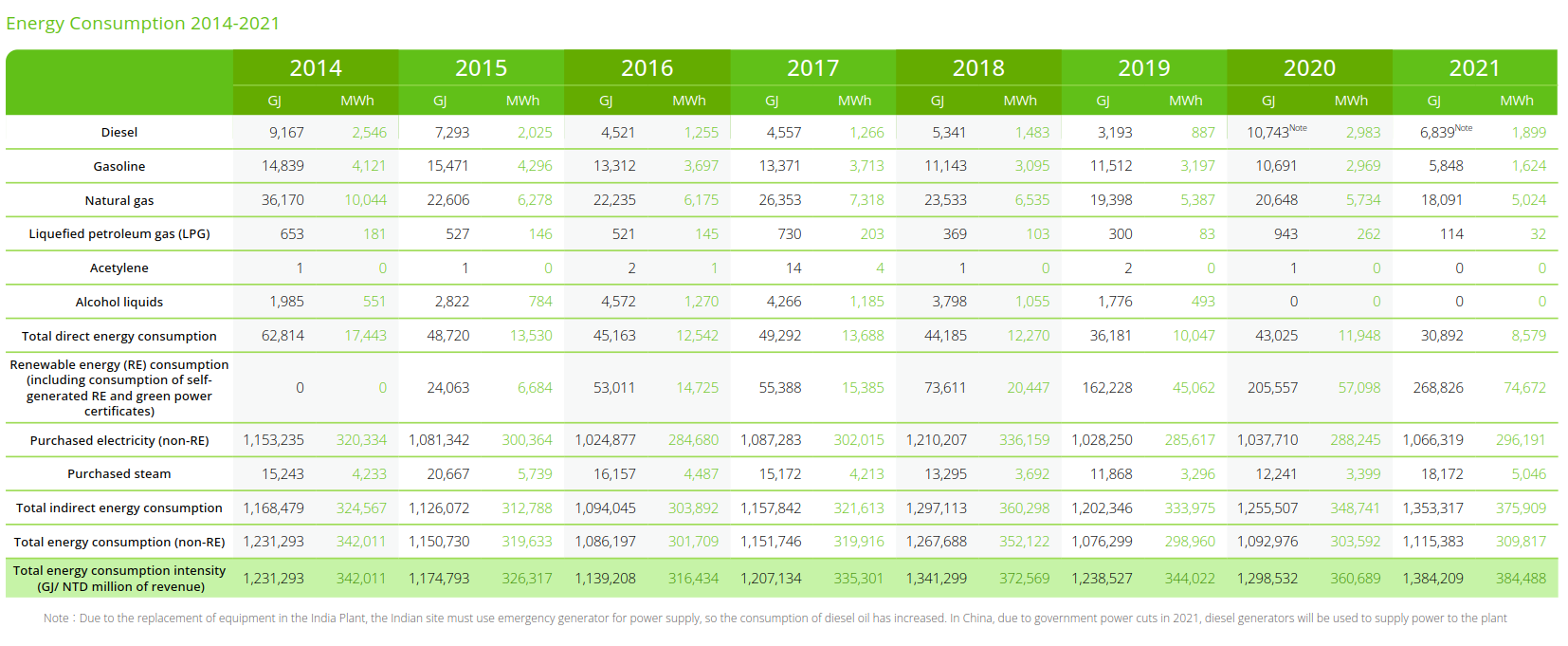

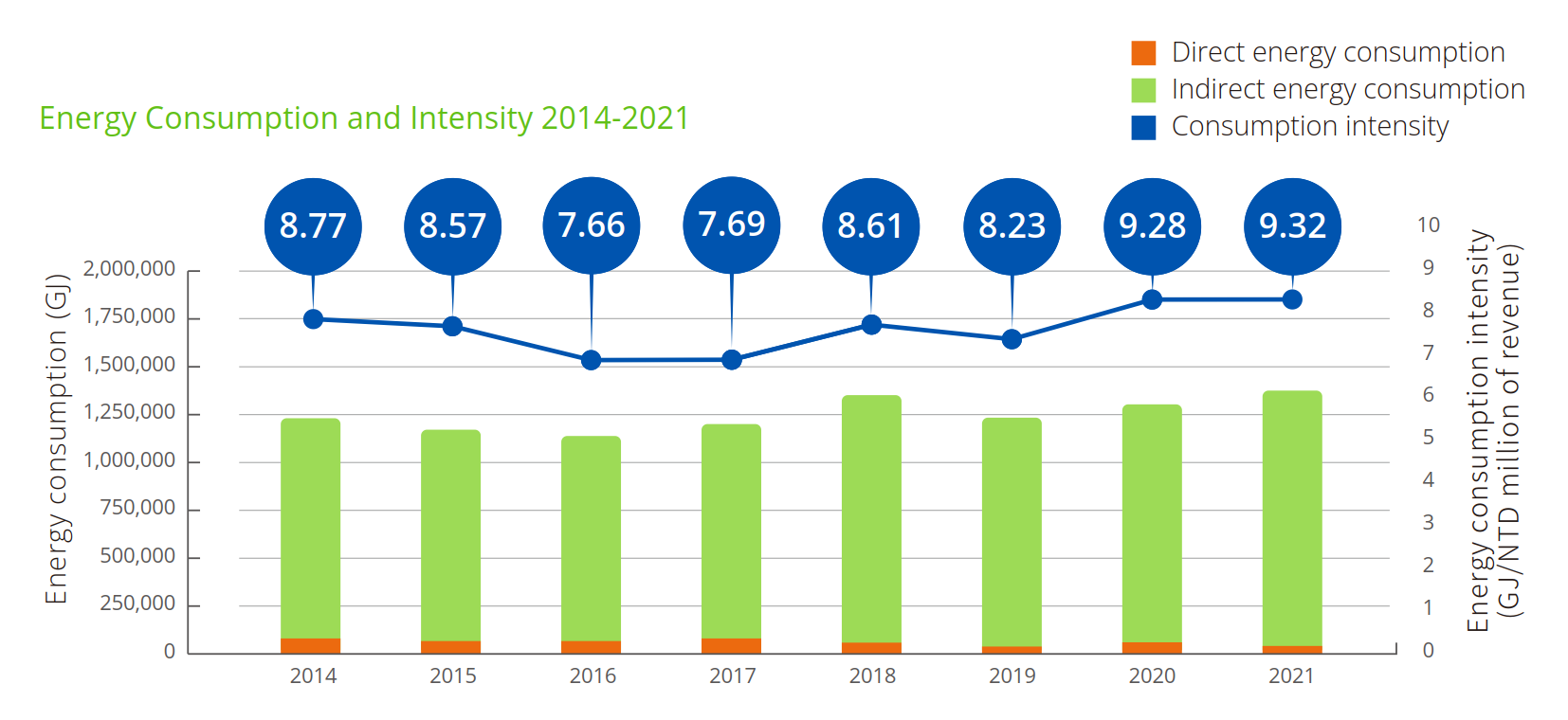

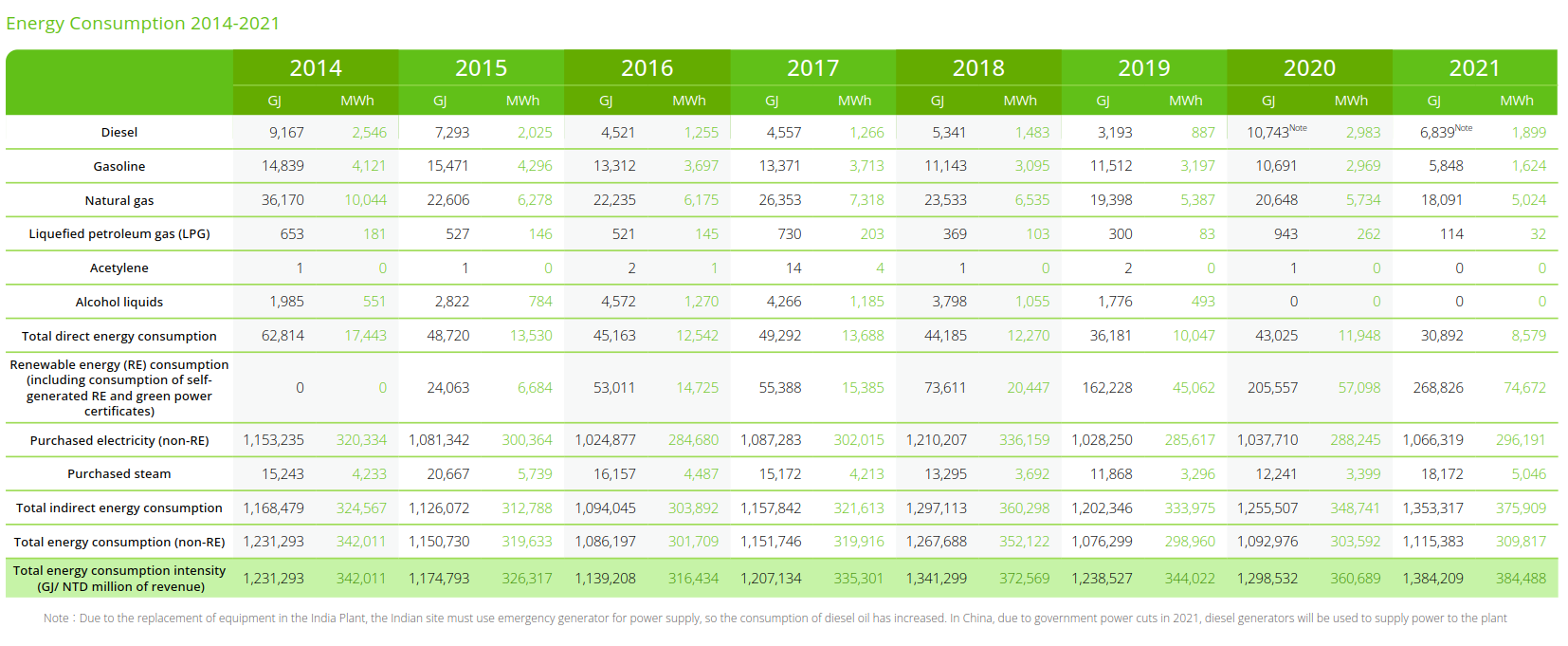

Direct and Indirect Energy Consumption

The bulk of energy consumption at LITEON operation and production bases is

provided by purchased electricity, followed by steam and natural gas. 95% or

more of total energy consumption at LITEON is indirect energy consumption.

Direct energy use of fossil fuels includes diesel, gasoline, natural gas, liquefied

petroleum gas (LPG), acetylene, and alcohol-based liquids, mainly used in

emergency generators, forklifts, buses, restaurants, and dormitory boilers.

In 2021, the inventory of total energy use of LITEON's bases was 1,384,209

gigajoules (GJ), an increase of 85,676 GJ (up by 6.60%) from 2020. The energy

consumption intensity was 9.32 NTD million of revenue, a increase of 0.39%

compared with the energy consumption intensity in 2020, which was mainly

due to the effective implementation of energy-conservation measures, etc.

Waste Management, Recycling and Reuse

LITEON follows the ISO 14001 standard and installs full-time units to be responsible for waste manageLITEON has followed the ISO 14001 standard to organize a specialized

unit that effectively tracks the source and volume of waste with the

criteria of maximizing the use of resources and minimizing waste

production. It promote green product design and waste management

measures, to minimize the production waste increase the life cycle of

each raw material, enhance the higher circulation and reuse the waste,

to achieve waste reduction targets. LITEON selects qualified waste

disposal operators that can effectively handle waste for disposal, and

conducts audits on the disposal operators through on-site or form-

based methods to confirm that waste disposal operators are properly

handling disposal, so as to ensure that the waste produced will not

have a significant impact on the surrounding environment.

LITEON's waste recycling solutions include reusing or reducing

packaging materials, plastics, cardboard and cartons, recycling alcohol

and selecting pallet to reduce waste generation. In the selection of

pallets, LITEON coordinates with upstream suppliers to use more

durable pallets. Using the Guangzhou plant as an example: more

durable plastic pallets are used to improve the utilization rate of

pallets. For loading, the cartons were changed to plastic cartons to

improve the recycling rate. The recycling rate of pallets reached 99.2%

and the reusing rate of plastic cartons reached 99.5%. In terms of

packaging, by reducing the use of cardboard, LITEON improved the

utilization rate of cardboard and reduce the procurement by about

20% a year. In terms of waste disposal, in addition to hiring qualified

waste collection and disposal service providers to handle incineration

and processing for reuse, LITEON adopts the responsible production

philosophy, and conducts regular supplier audits to ensure waste is

properly handled.

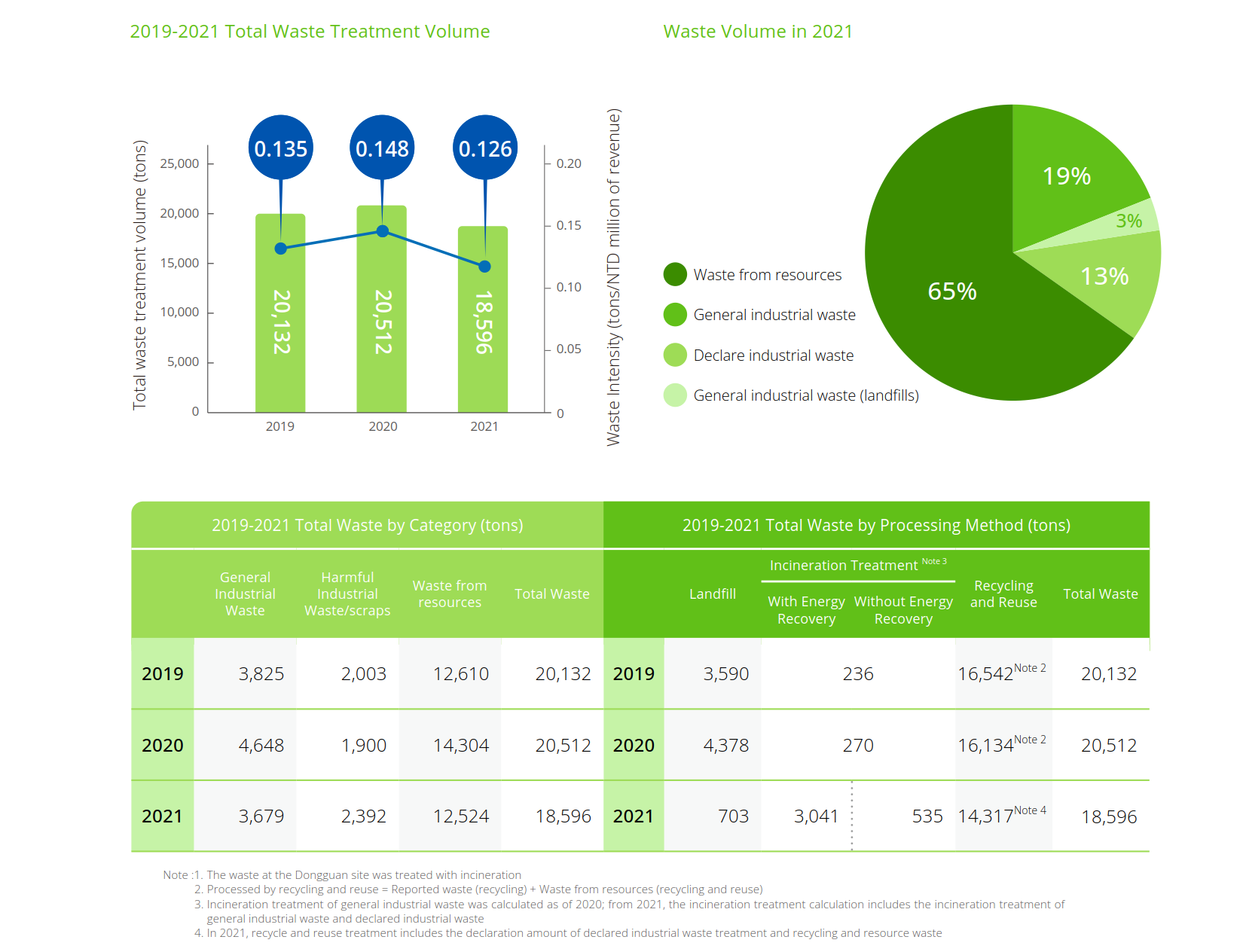

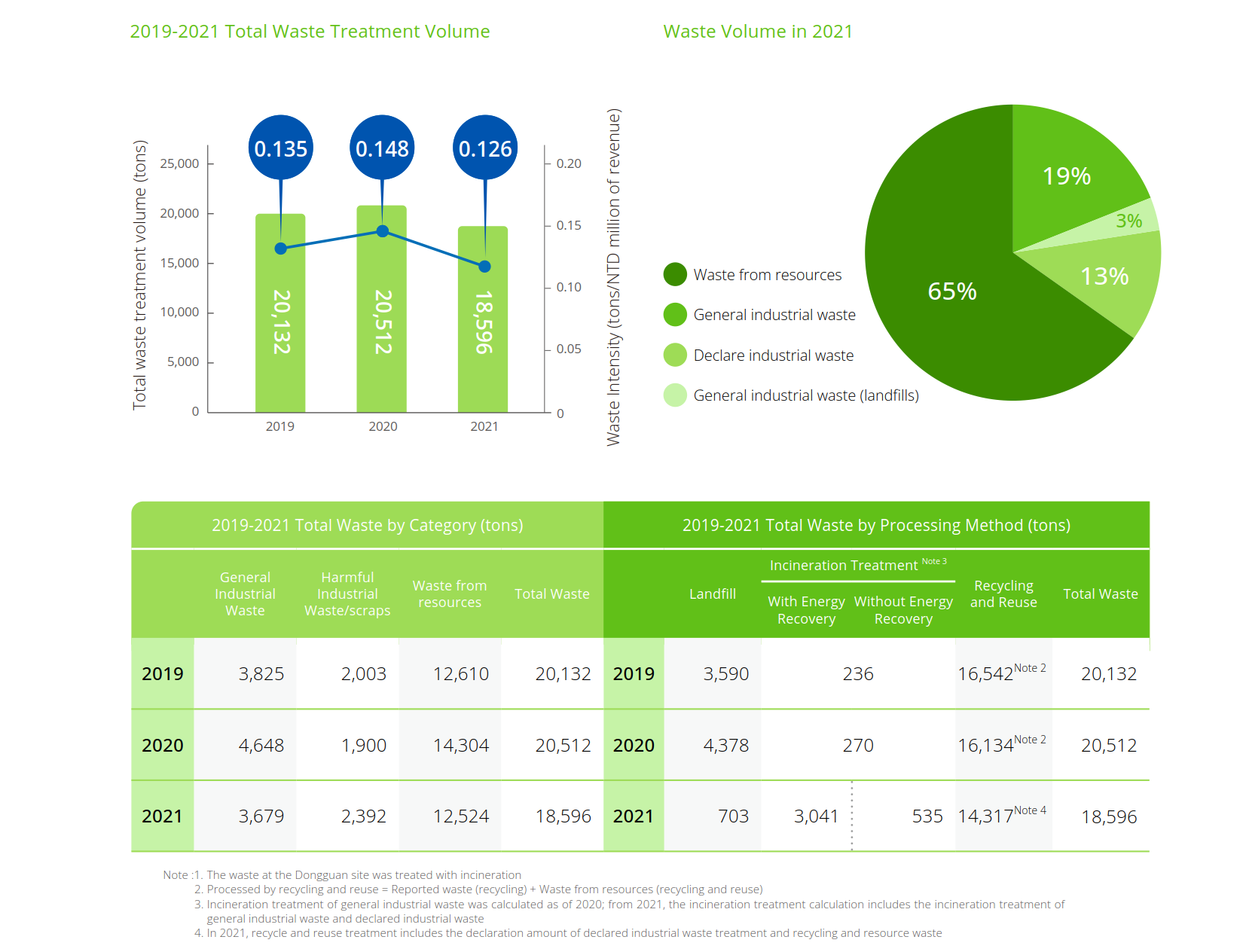

LITEON defines waste as materials after operation or production that

will no longer enter the process stage. The total amount by category

is calculated by waste disposal service providers upon exiting the

premises. General industrial waste treatment methods include

landfill treatment and incineration treatment (with / without energy

recovery), and hazardous industrial waste treatment methods include

landfill treatment, incineration treatment (including/not including

energy recovery), and resource and regenerating. The total waste

volume in 2021 was 18,596 tons, a reduction of 1,916 tons (9.34%

reduction) compared to the total waste volume in 2020. The waste

intensity was 0.126 tons / NTD million of revenue in 2021, down by

14.97% compared to 2020. LITEON will continue to improve waste

management and work towards the goal of reducing absolute waste

intensity by 10% by 2023 as compared to 2020.

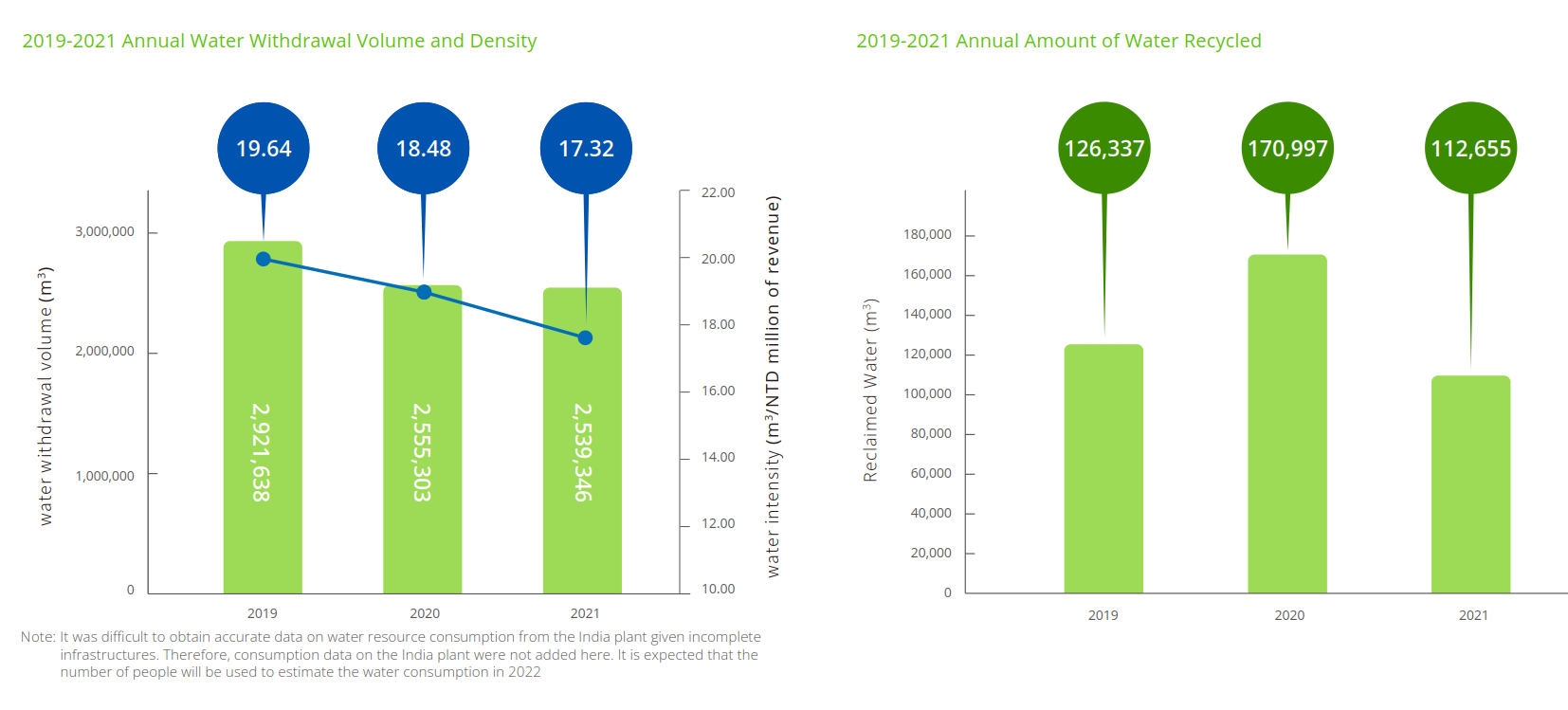

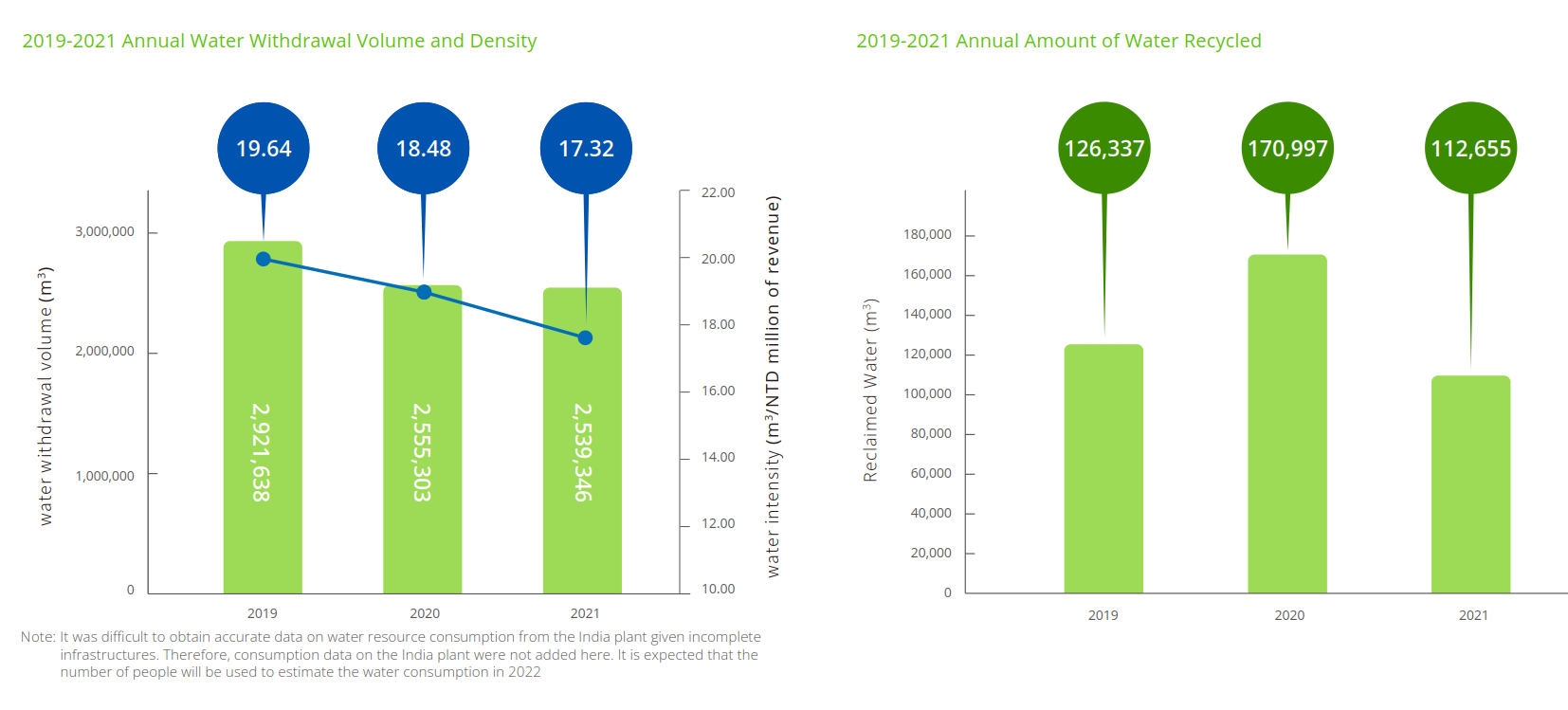

Water Resource Conservation

LITEON builds its water resource management system on ISO 14001 standards. A central control system monitLITEON has established an environmental management system based on ISO 14001 to manage water resources

and monitor the data of each plant through a data-based central control system and track water management

performance at significant sites around the world. LITEON continues to promote the improvement of water

quality and water conservation measures. These measures include replacement and updating of old pipes,

spot check of water outlets and routine inspection of water usage and water recycling and reuse. LITEON also

strengthens daily management practices such as training. Water resources are mostly used for factory facilities

and employees, and relevant measures are concentrated on circulating water including air-conditioning systems

and air compressors and domestic water for employees. Total water consumption in 2021 was 2,539,346 m3

(0.62% lower than 2020) and the intensity was 17.32 m3 NT D million of revenue (6.23% lower than 2020).

Wastewater Treatment and Resourcization

Water consumption at LITEON plants was sourced 100% from the local water system (i.e. tap water) and used

primarily for employees' daily needs and for plant equipment. All wastewater produced is either properly treated

or discharged to sewer areas according to the law and entered into the municipal wastewater treatment program.

A small amount of industrial wastewater is treated by the wastewater treatment facilities inside the plants (by

methods such as sedimentation or chemical coagulation), and discharged when the treated wastewater meet

the local regulatory requirements. The discharge of water has no significant impact on the water body. In order

to implement the effective management and resourcization of discharged wastewater, improvement of water

management includes measures such as inspecting water-saving appliances, strengthening leakage prevention

equipment, improving the recovery rate of process water and reducing the water escape rate of cooling towers.

The total water recovered in 2021 was 112,655 m3 (34% lower than 2020).

Environmental Management Targets and Implementation

Environmental Sustainability ▸

言語を選択する