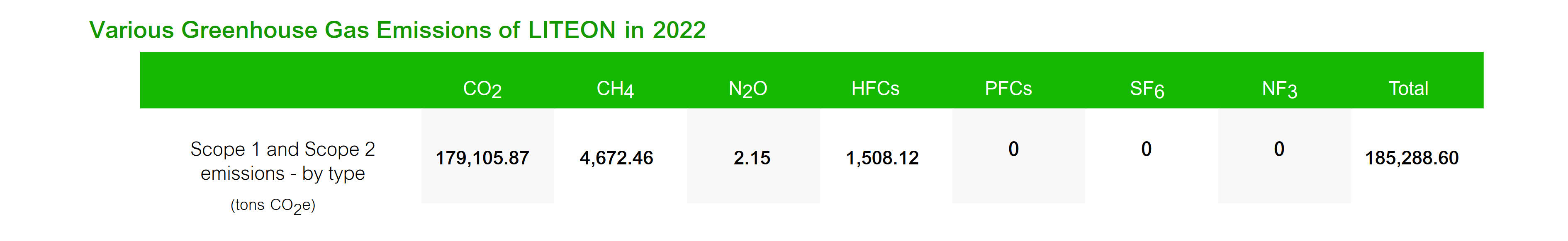

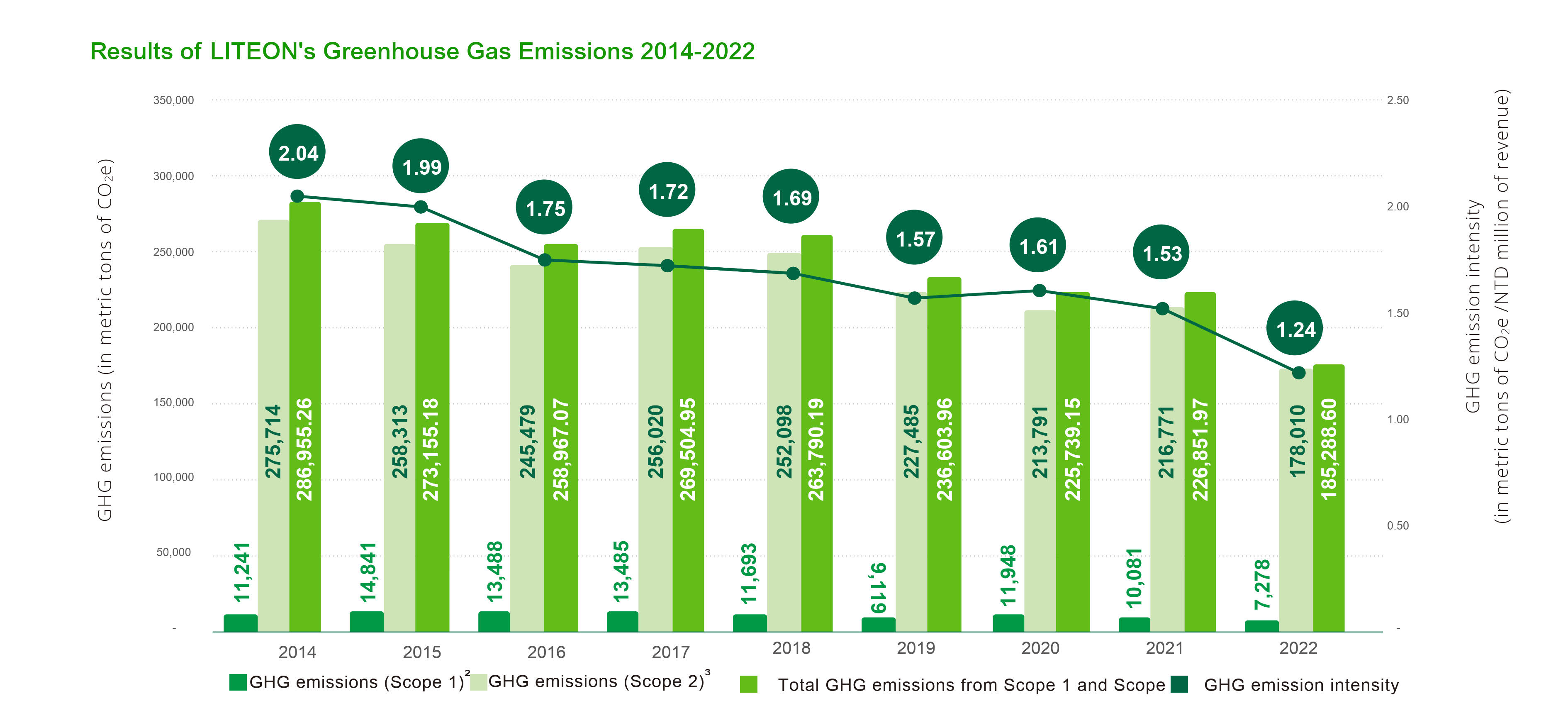

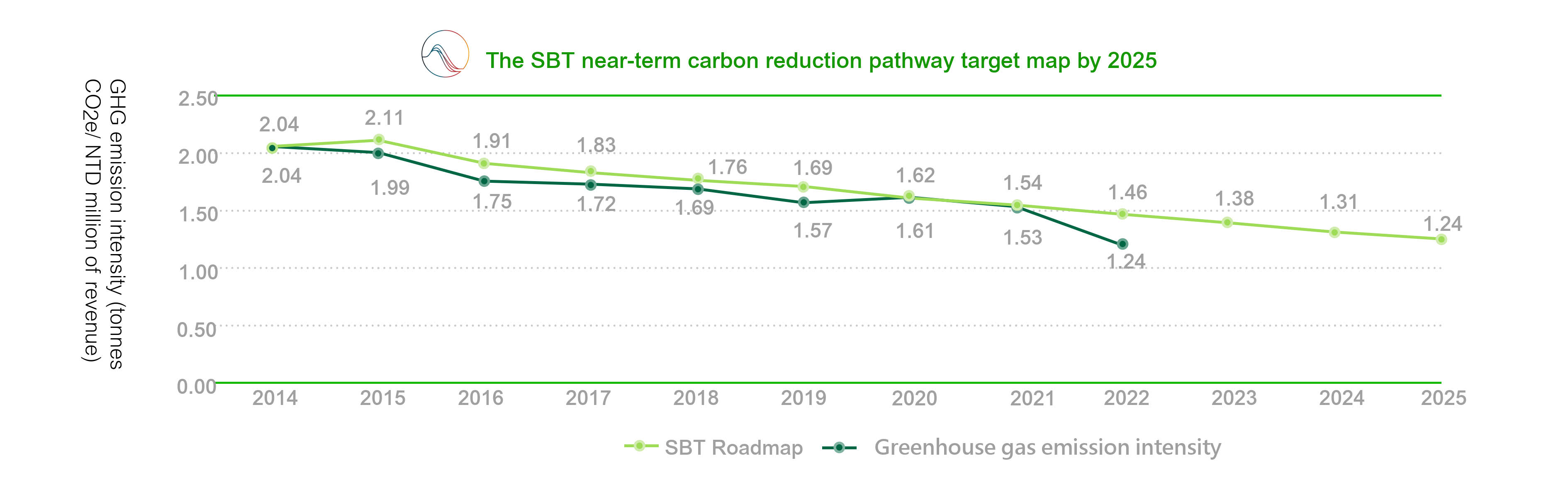

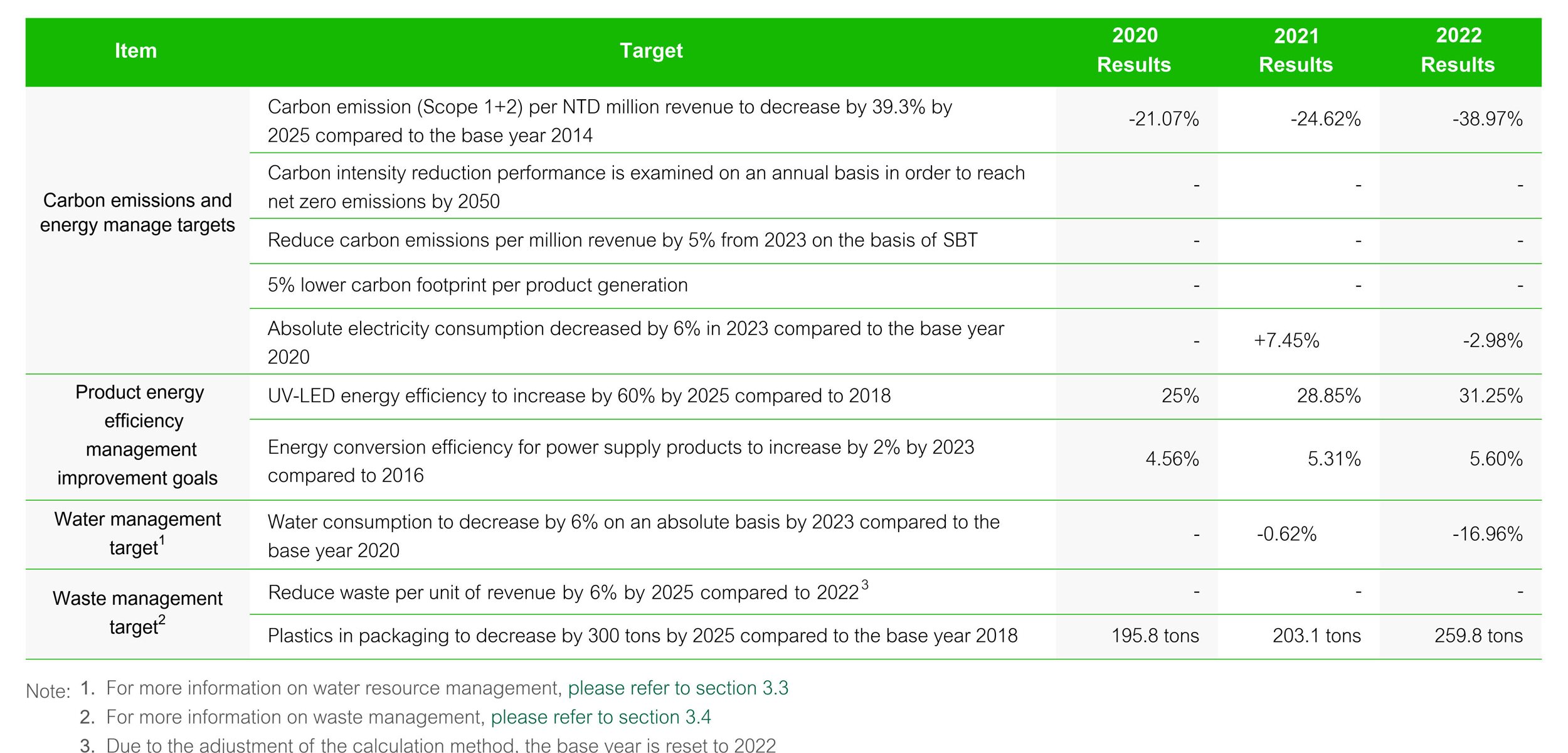

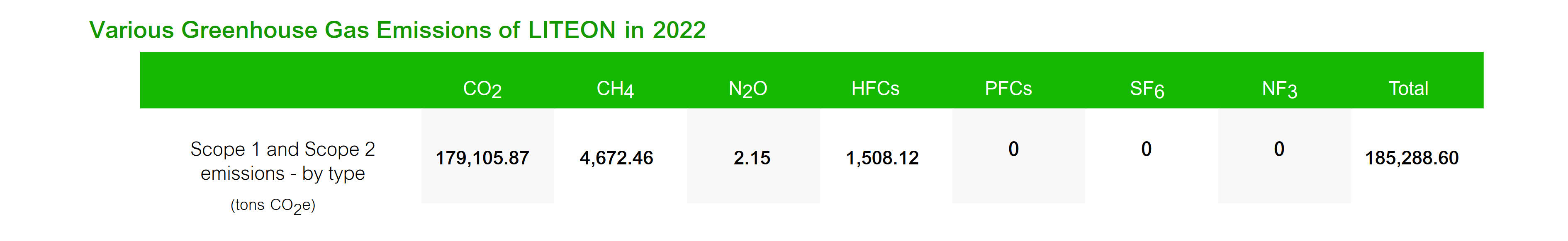

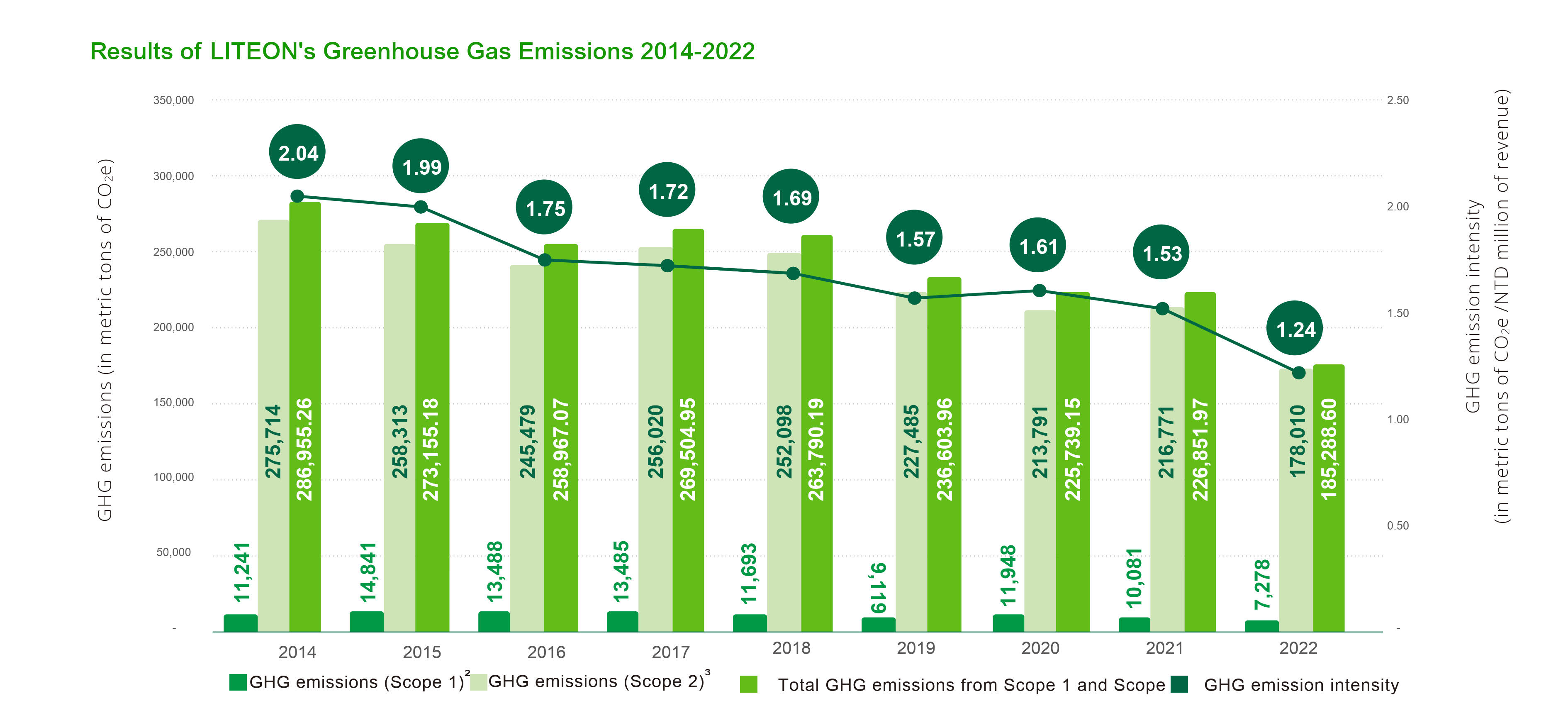

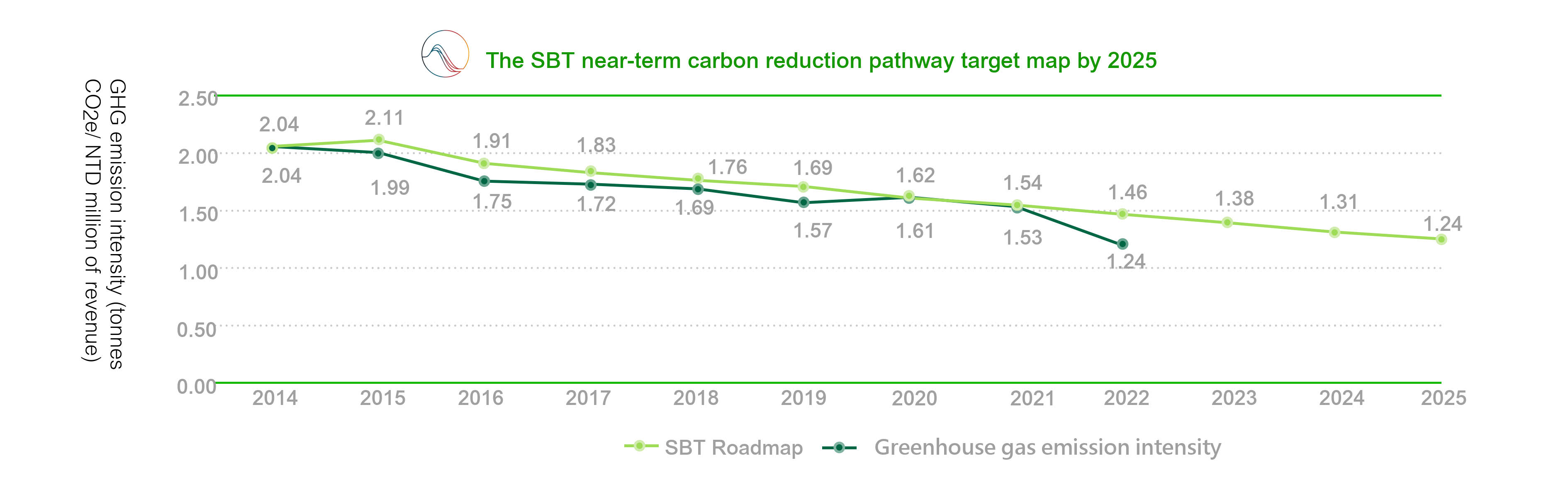

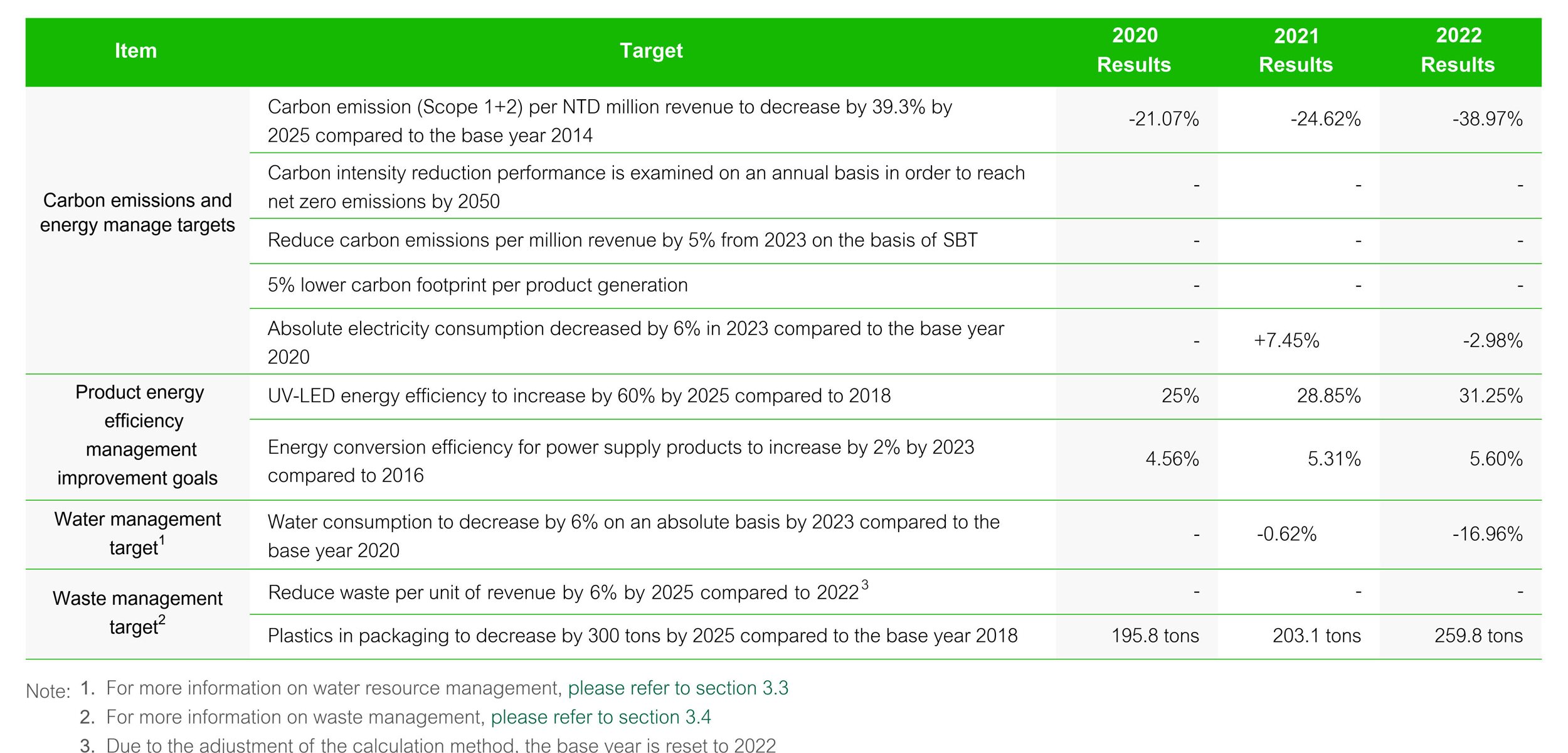

Greenhouse Gas Inventory (GHG Scope 1 and Scope 2)

According to the ISO 14064-1:2018 standard for GHG emissions

inventory, in 2022, LITEON's direct GHG emissions (Scope 1) and

indirect GHG emissions (Scope 2) were 185,288.60 tons CO2e (marketbased),

a decrease of 41,563.37.15 tons of CO2e compared to 2021

(down by 18.32%), and 101,666.66 tons of CO2e (down by 35.43%) less

than the base year 2014. The carbon intensity was 1.24 tons CO2e /NTD

million of revenue, 18.45% lower than in 2021 and 38.97% lower than

the base year 2014. The boundary sets as the manufacturing plants and subsidiaries where revenue accounts for more than 1% comparing with the total revenue. The figures complied with the SBT reduction path

target of 28.51% for 2022. We increase carbon intensity target to 5% per

year in 2023.

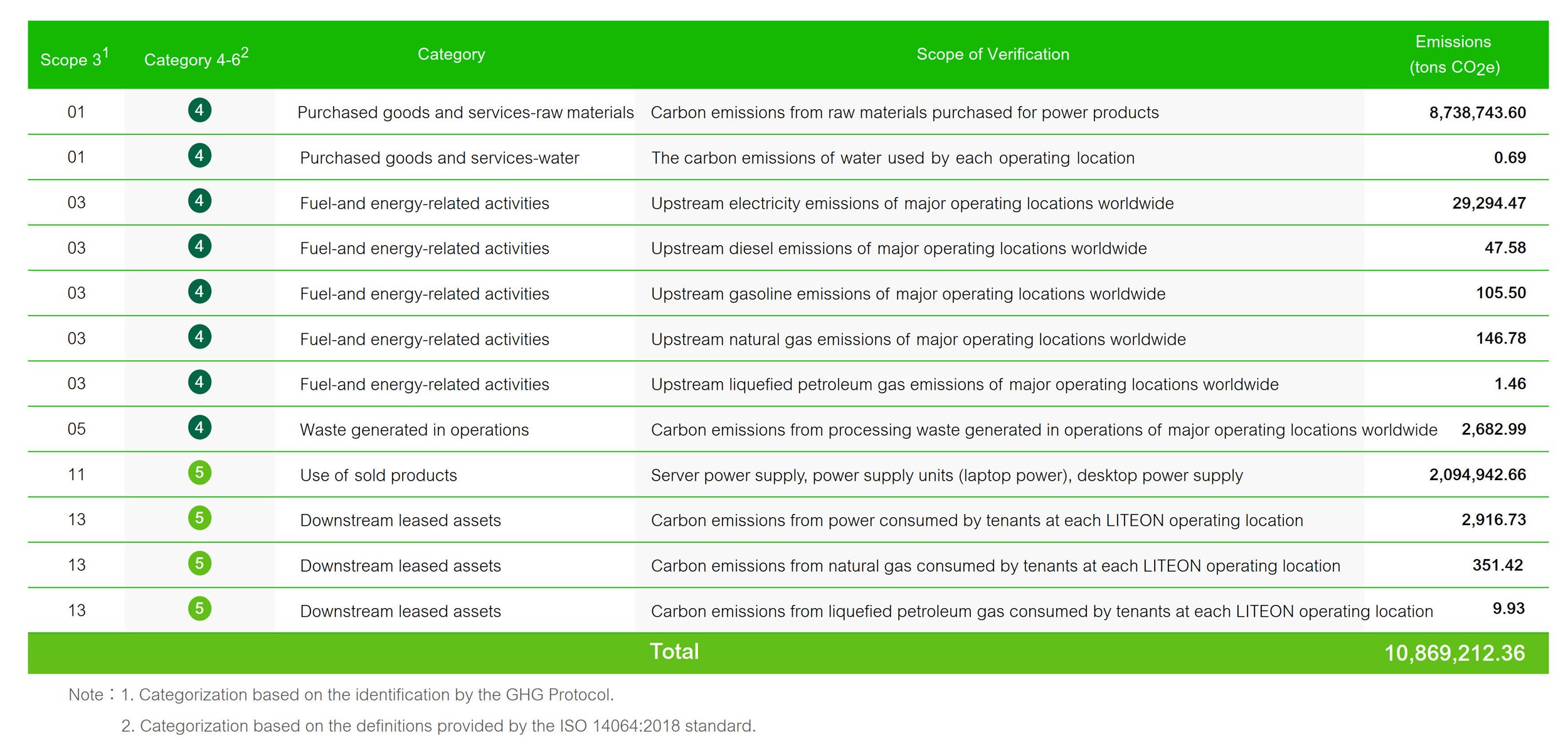

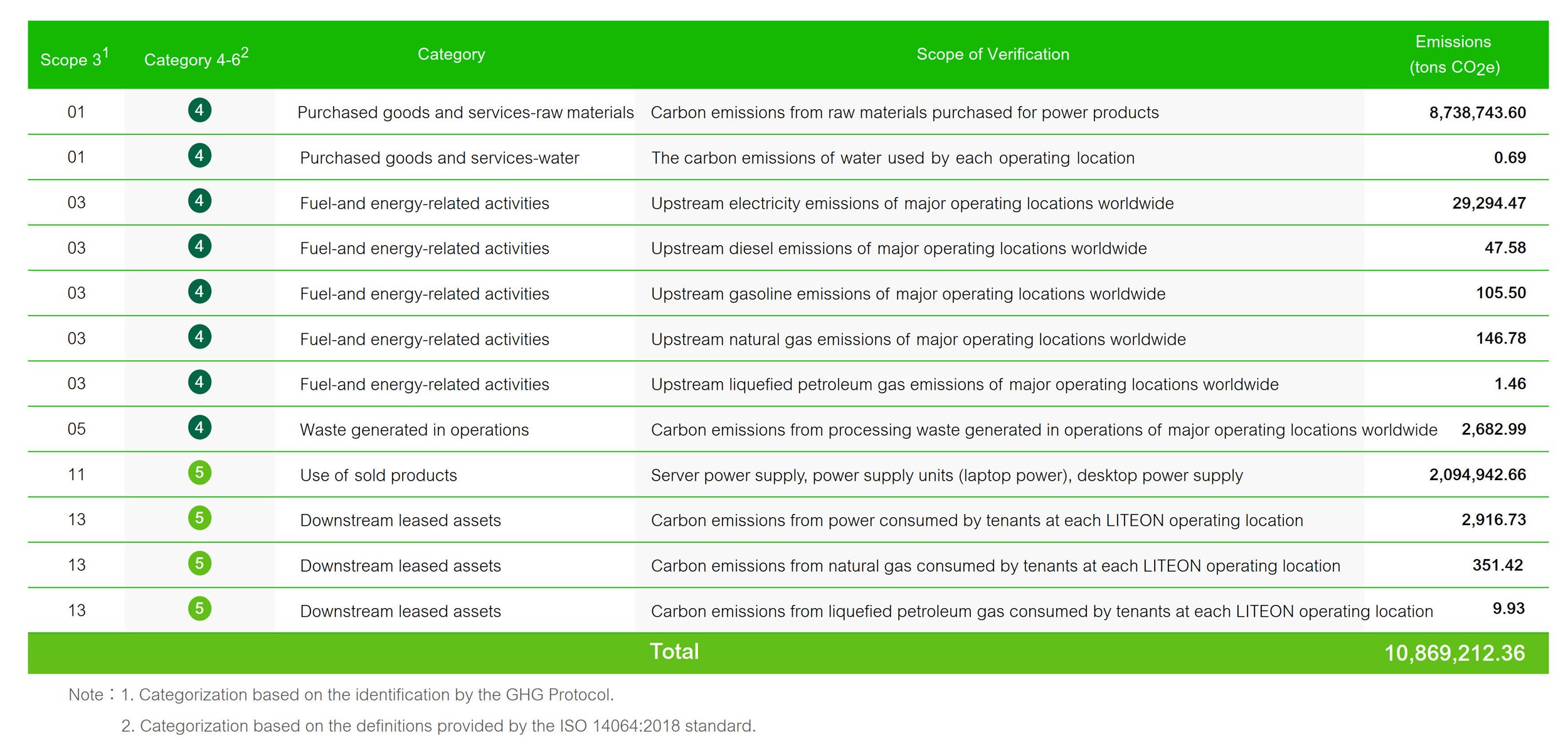

Greenhouse Gas Value Chain Inventory (GHG Scope 3)

To maximize the value of the LITEON value chain and identify key factors to mitigating climate change, LITEON not only conducts inventories of emissions from its own business activities and but also references ISO 14064:2018 and GHG

Protocol standard. The practice allows LITEON to follow emission hot spots along the value chain and extend carbon management to business partners on the value chain through verification, and disclosure of emissions.

LITEON used materiality identification standards, consideration of assessment factors such as emissions, improvement potential, and quantification methods, to identify emissions from upstream raw materials used in products and services,

emissions from upstream water treatment, and emissions from upstream fuel and energy activities for 2022's Scope 3 inventory. With a total of 12 categories revealed in Scope 3/ Categories 4 to 6, LITEON continues to work with value chain

partners to develop low-carbon products through strategies such as green product design to combat climate change and global warming.

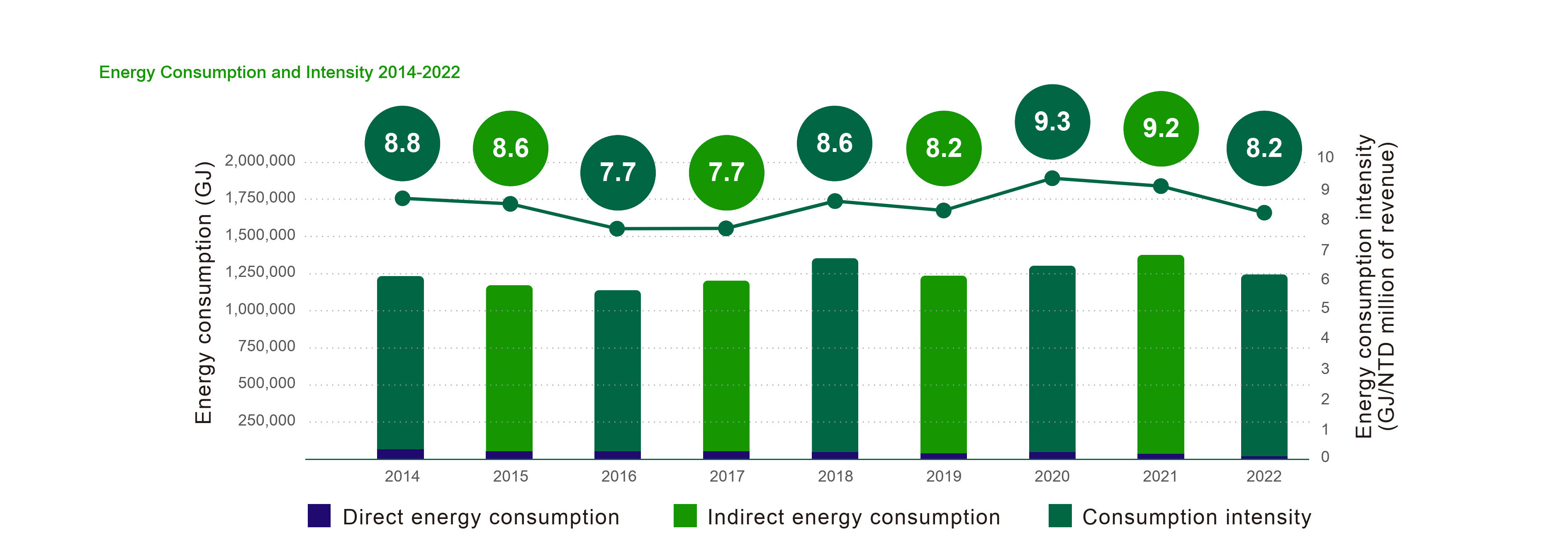

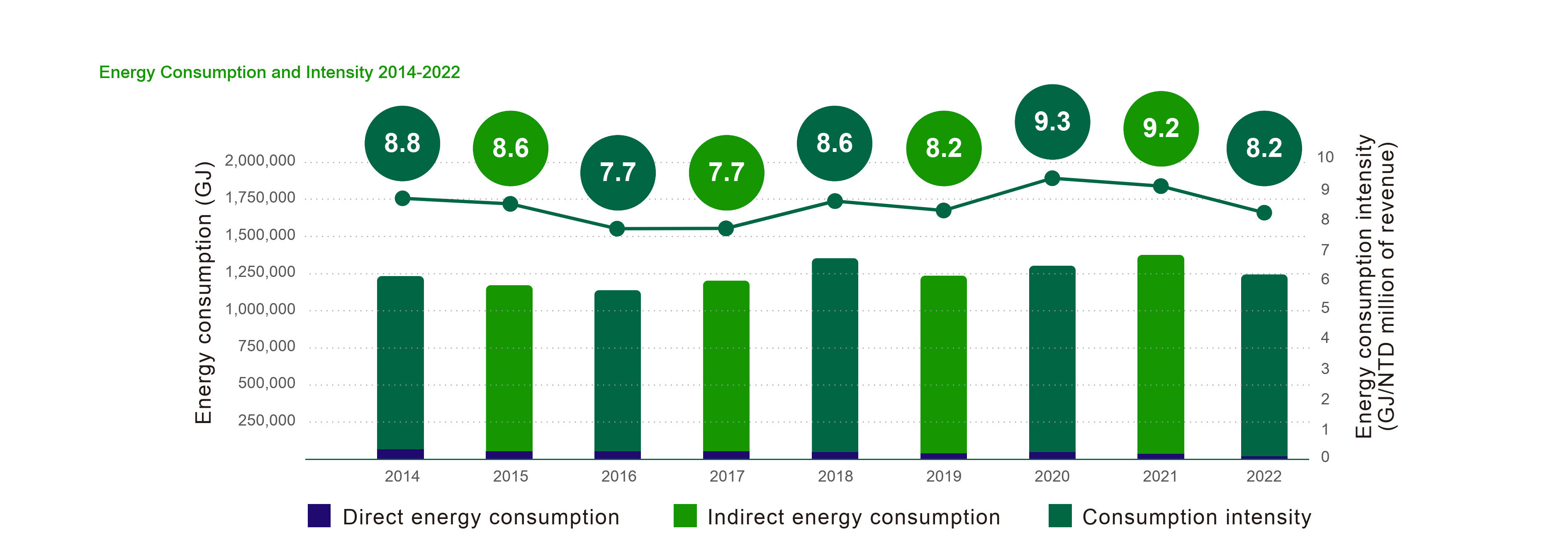

Direct and Indirect Energy Consumption

The majority of energy consumption at LITEON's operation and production sites comes from purchased electricity,

followed by steam, with 97% or more of the total energy consumption being indirect. LITEON's direct energy

consumption comes from the use of fossil fuels such as diesel, gasoline, natural gas, liquefied petroleum gas

(LPG), acetylene, and alcohol-based liquids, primarily used in emergency generators, forklifts, buses, restaurants,

and dormitory boilers. In 2022, the total energy consumption inventory of LITEON's bases was 1,213,542 GJ, a

decrease of 147,541 GJ (10.8% drop) from 2021. The energy consumption intensity was 8.15 GJ/NTD million of

revenue, a 10.98% decrease compared to the energy consumption intensity in 2021. This decrease was primarily

due to the effective implementation of energy-conservation measures.

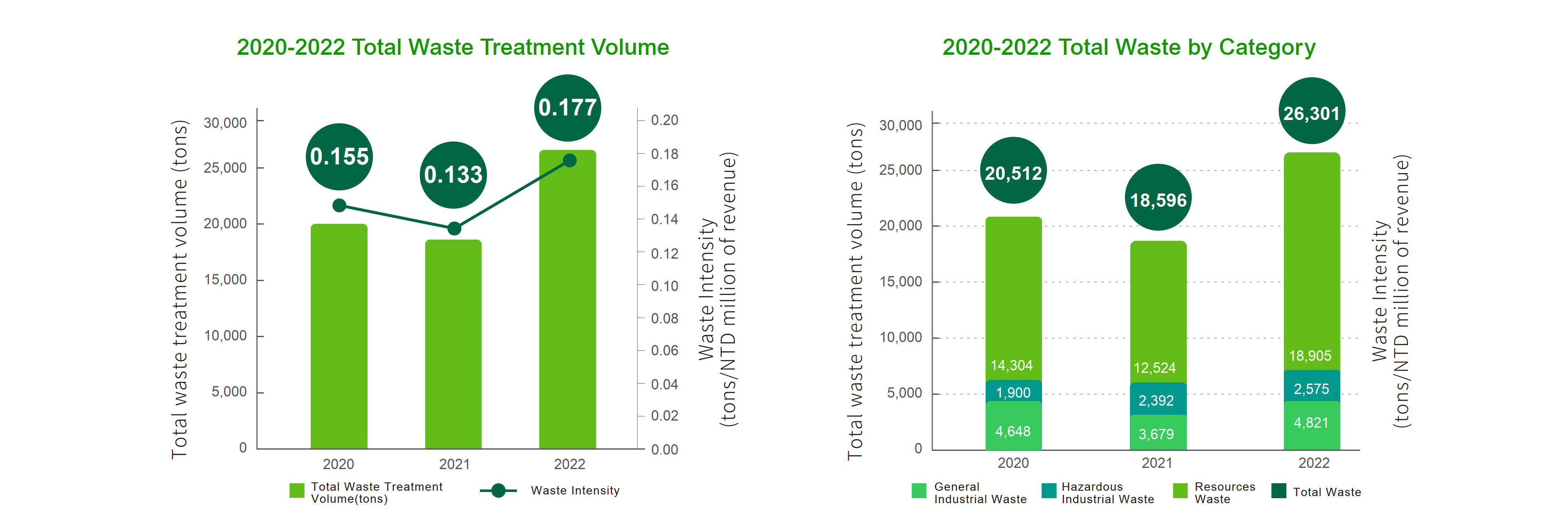

Waste Management, Recycling and Reuse

LITEON has followed the ISO 14001 standard to organize a specialized unit that effectively tracks the source and volume of waste with the criteria of maximizing the use of resources and minimizing waste production. It promotes

green product design and waste management measures, to minimize the production waste increase the life cycle of each raw material, enhance the higher circulation and reuse the waste, to achieve waste reduction targets. LITEON

selects qualified waste disposal operators that can effectively handle waste for disposal, and conducts audits on the disposal operators through on-site or formbased methods to confirm that waste disposal operators are properly

handling disposal, so as to ensure that the waste produced will not have a significant impact on the surrounding environment.

To further implement LITEON's waste recycling philosophy, we

introduced UL 2799 Zero Waste to Landfill statistic at our sites.

We achieved the platinum level in the Dongguan factory, and also

introduced this statistical method to other factories. Therefore, we

can calculate waste statistics on the site more accurately. We not

only increase the waste conversion rate and reduce the waste output,

but also reduce the amount of resource recovery and improve the

resource recovery rate. When carrying out removal, we also ensure

that the waste disposal method of disposal service providers

complies with local regulations.

LITEON's waste recycling solutions include reusing or reducing

packaging materials, plastics, cardboard and cartons, recycling

alcohol and selecting pallet to reduce waste generation. In the

selection of pallets, LITEON coordinates with upstream suppliers to

use more durable pallets. Using the Guangzhou plant as an example:

more durable plastic pallets are used to improve the utilization rate

of pallets. For loading, the cartons were changed to plastic cartons

to improve the recycling rate. In terms of packaging, by reducing the

use of cardboard, LITEON improved the utilization rate of cardboard

and reduce the procurement by about 20% a year. In terms of waste

disposal, in addition to hiring qualified waste collection and disposal

service providers to handle incineration and processing for reuse,

LITEON adopts the responsible production philosophy, and conducts

regular supplier audits to ensure waste is properly handled.

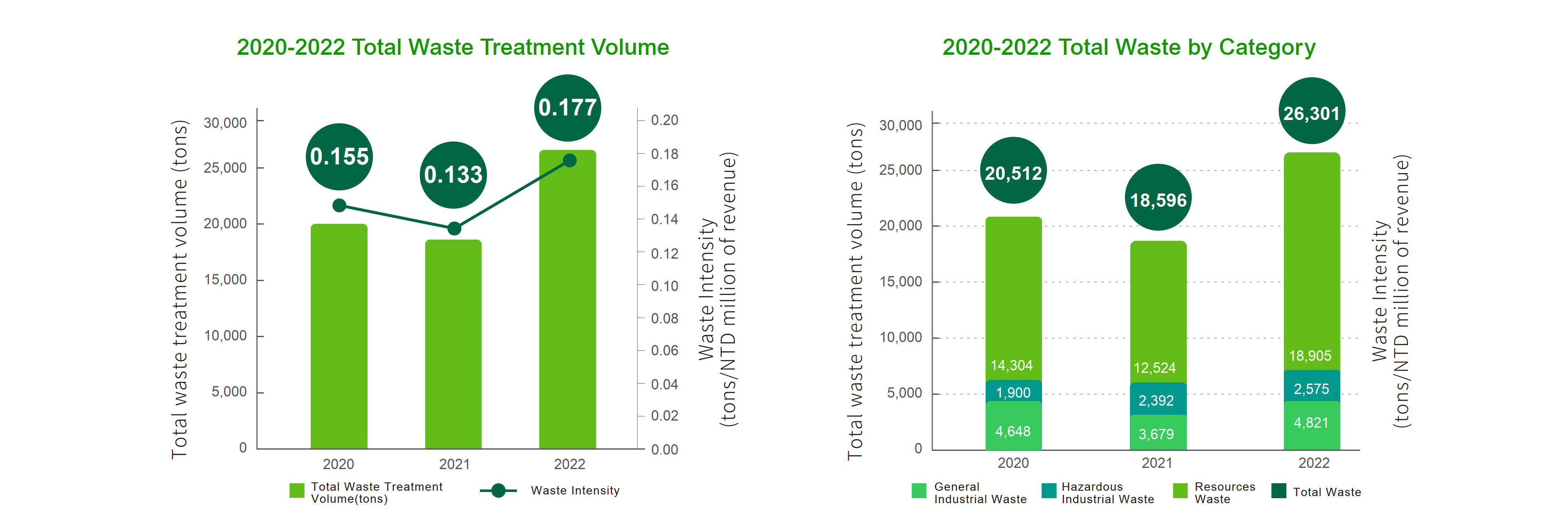

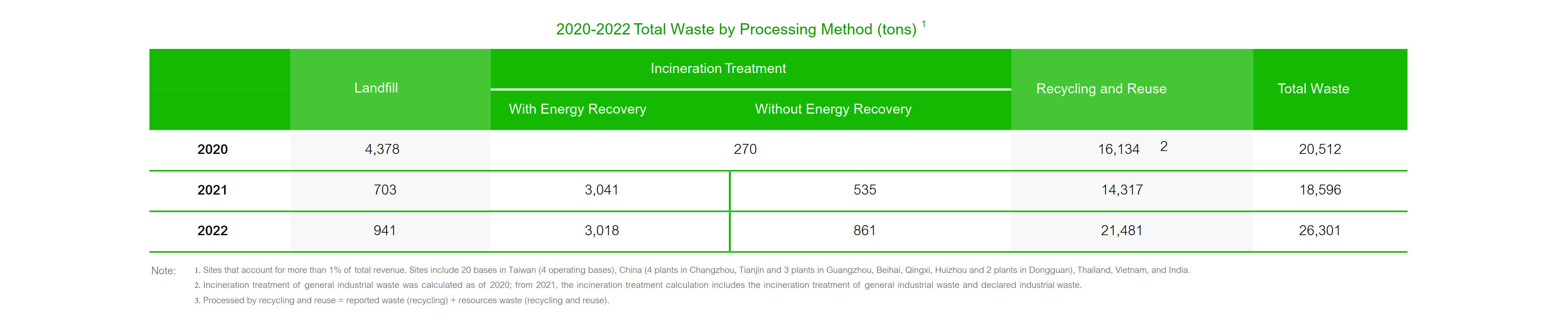

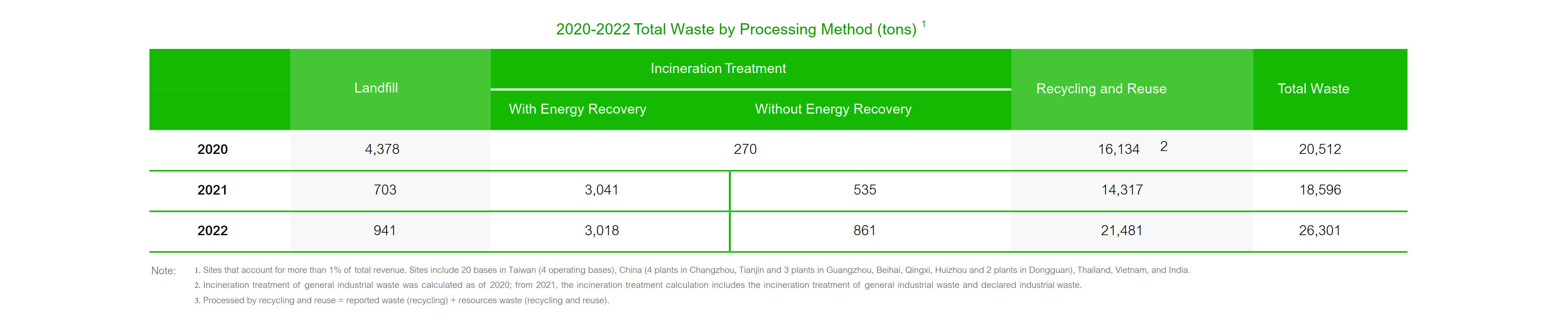

LITEON defines waste as materials after operation or production that

will no longer enter the process stage. The total amount of waste

discharged is calculated as the total weight of waste weighed by

the waste treatment unit at the time of leaving the factory. Waste

treatment methods include landfill, incineration (including/not

including energy recovery), and recycling for reuse of resources.

Due to the introduction of the concept of zero waste to landfill, the

statistical method is inconsistent with the base year data, so the waste

target has been re-set to reduce waste intensity by 2% per year with

2022 as the base year. The total waste volume in 2022 was 26,301

tons the waste intensity was 0.177 tons / NTD million of revenue in

2022. LITEON will continue to improve waste management and work

towards the goal of reducing absolute waste intensity by 6% by 2025

as compared to 2025.

Water Management and Target

Water Management

LITEON has established an environmental management system based on ISO 14001 to manage water

resources. Water consumption at LITEON plants was sourced from tap water and used primarily for

employees' daily needs and for plant equipment. On the drainage system, LITEON ensures ensure that

the quality of effluent meets requirements of local environmental protection agencies and does not cause

environmental burden. A small amount of industrial wastewater is treated by the wastewater treatment facilities

inside the plants (by methods such as sedimentation or chemical coagulation), and discharged when the

treated wastewater meet the local regulatory requirements. All wastewater produced is either properly treated

or discharged to sewer areas. The discharge of water has no significant impact on the water body.

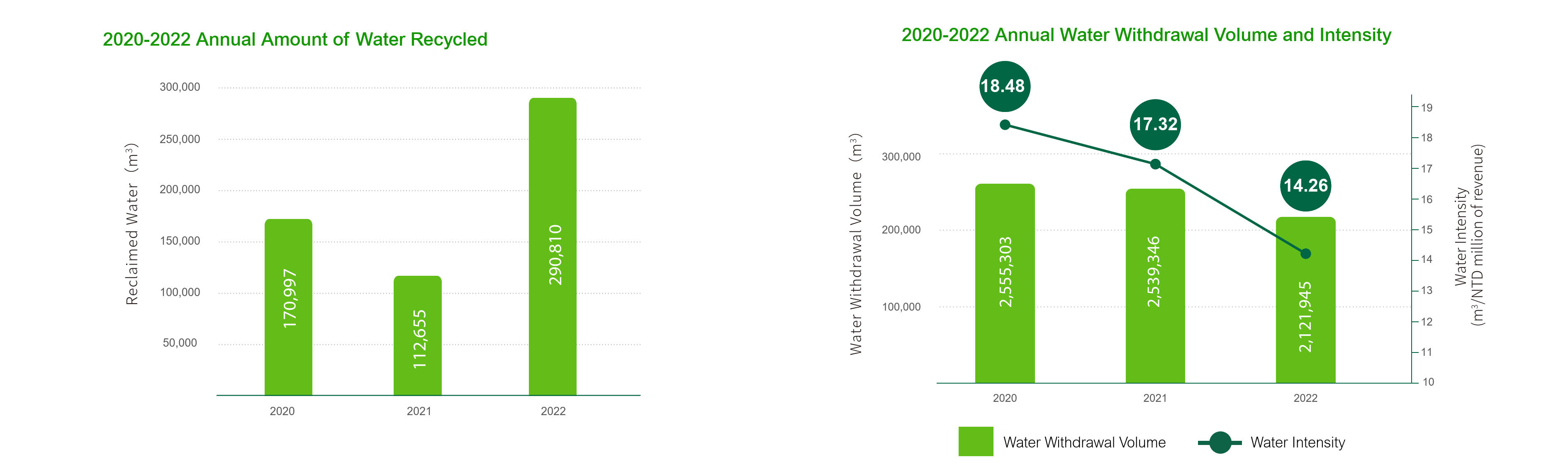

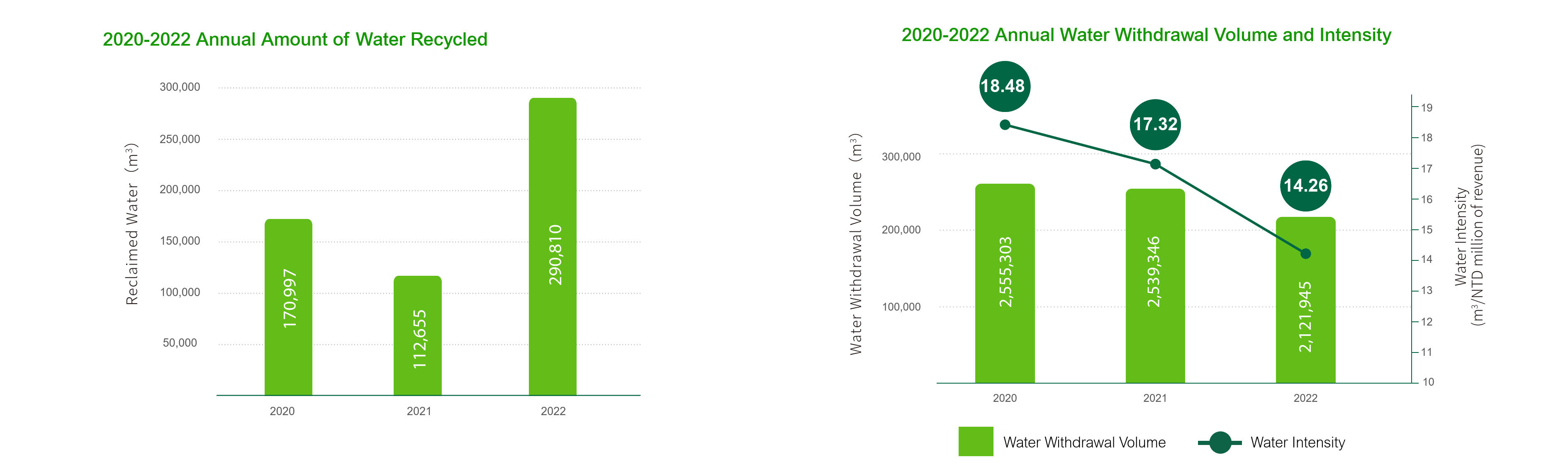

In 2022, water recycling volume is counted each cycle, and the efficiency of equipment for recycling water is improved.

Thus, the amount of water recycled has increased significantly compared to 2021. Total water consumption in 2022 was 290,810 m3, an increase of 178,155 compared to 2021 (increased by 158.14% by 2021).

Water Risk Assessment

Areas with higher risk in LITEON's water resource management are identified using external tools and internal evaluation methods. External tools used to analyze the potential impact of main locations of operations on water resources include WRI tools and the scenario RCP 8.5 in the IPCC guidelines; internal evaluation is conducted via on-site evaluations, which identify higher risk areas in LITEON's water resource management include Tianjin, Vietnam, Thailand and India. LITEON improves the water quality in areas with higher risk, in order to lower the burden on the air conditioning system, improving equipment efficiency and reducing water evaporation. The India plant has proposed a response plan for water quality improvement, and installed water

quality conversion equipment in 2022 to reduce risks to the environment and employees.

Target execution and monitoring

In 2021, LITEON set a target of 6% absolute water reduction by 2023 (2% reduction per year) based on 2020.

To reduce LITEON's water withdrawal volume in each area. In terms of tracking and management, LITEON

uses a centralized data system to obtain plant data and monitor the water resource consumption of major

locations of operations worldwide. We compare it with water withdrawal information in the previous year

to maintain reasonable use of water resources and track water conservation/recycling results. Total water

consumption in 2022 was 2,121,945 m3(16.4% lower than 2021) and the intensity was 14.26 m3 NTD million of

revenue (17.7% lower than 2021).

LITEON promotes the improvement of water quality and water conservation measures. These measures include implementing the effective management and resourcization of discharged wastewater, inspecting

water-saving appliances, strengthening leakage prevention equipment, improving the recovery rate of process

water and reducing the water escape rate of cooling towers. LITEON also strengthens daily management

practices such as training. A reduction of 433,358 m3 (17%)compared to the total water consumption volume

in the base year 2020. Water intensity in 2022 was 22.83% lower than 2020.

Environmental Management Targets and Implementation

Environmental Sustainability ▸

Select Language