Occupation safety and health management

LITEON places an emphasis on its EHS performance management. The company is dedicated to providing safe, comfortable, environmentally friendly, and effective production sites for the benefit of our employees, customers, partners, and the community. EHS management is considered part of the company's competitive advantage, and is hardwired into the corporate DNA. LITEON has created an MOE Department. In addition to setting strategic business targets, the department monitors potential impact on the business activities, such as environmental conservation and occupational health and safety issues. Furthermore, the department ensures the EHS targets are met to the satisfaction of the management, and reports regularly to the Group CEO results in areas including overall conditions of plants in the group and occupational health and safety.

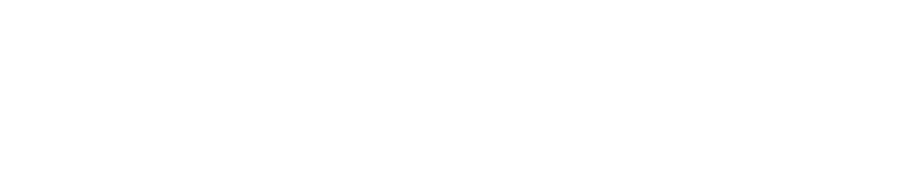

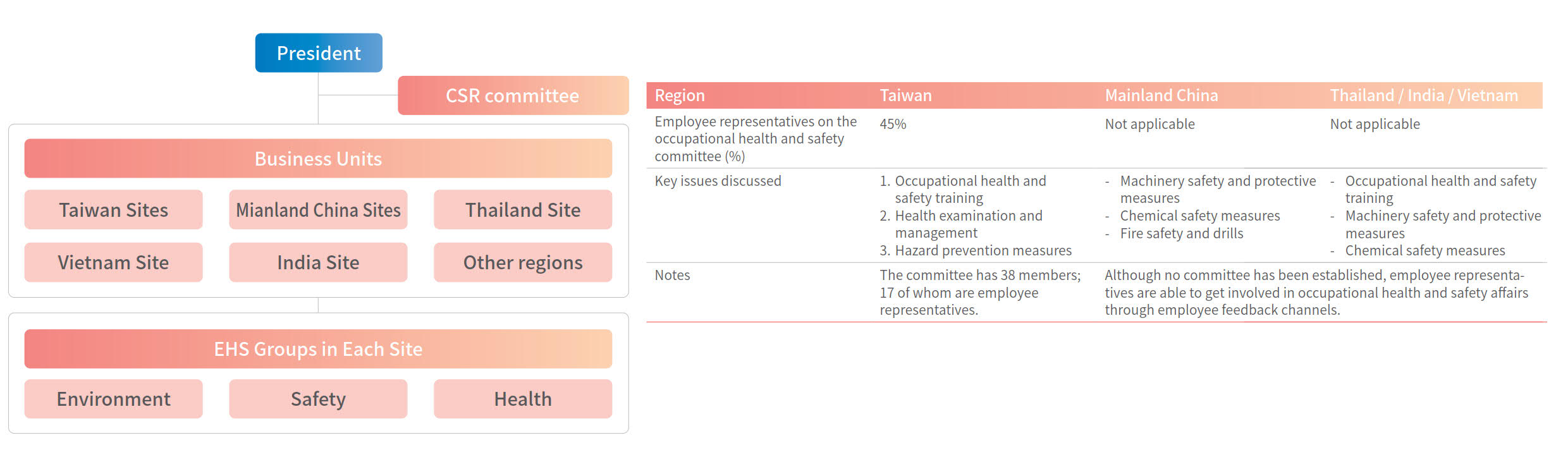

Occupation safety and health framwork

Occupation safety and health system

To protect workers' safety in the workplace, LITEON, in addition to implementing the Occupational Safety and Health Management Policy, have top plant managers at all production sites install EHS organizations and occupational safety and health management committees. The company also put occupational safety and health officers in place to be responsible for promoting and obtaining ISO 45001, OHSAS 18001 or other international certification. The goal is to reduce occupational hazards by ensuring all work plans are carried out effectively and improvements made through the management cycle.

Worker participation, counseling and communication in occupational health and safety

Most LITEON's production sites are located in Taiwan, China and Thailand. The laws in Taiwan require companies have an occupational health and safety committee in place to oversee and coordinate occupational health and safety related matters. Regular meetings are held to discuss health and safety issues, including health and safety management, education and training programs, health management, prevention of occupational diseases and health facilitation, automated examination and health and safety audits, machines, equipment or raw materials, prevention of material hazards, and occupational accident investigation reports. Though no such requirement exists in China or Thailand, LITEON has nevertheless created similar organizations to involve employees in the company's occupational health and safety practices. Above is a summary of workers' participation in health and safety organizations throughout LITEON's global locations, and the key issues discussed in 2020.

Hazard identification, risk assessment and incident investigation

of early prevention, zero accident and zero hazard. The scope covers routine operations in the

company as well as other personnel (contractors and visitors) conducting their activities in LITEON's facilities. Management representatives are put in charge of reviewing the approval

processes for hazard identification and risk assessment. EHS and unit heads at the plants will perform the necessary tasks after they are confirmed.

The plants hold regular health and safety meetings. Internal/External audits are conducted to examine the adequacy of hazard identification and risk assessment. The plants discuss and revise the processes as needed. All plants comply with the requirements of local regulations and ISO 45001 standards. The plants perform risk assessments to achieve the vision and target of zero accident and zero hazard.

Orientation training informs new employees of their duties regarding health and safety, and emphasizes the importance of protecting themselves. In accordance with the guidelines for

"potential imminent danger" under Article 18 of the Occupational Safety and Health Act and Article 25 of the Enforcement Rules of the Occupational Safety and Health Act, the company informs all employees that they should report any imminent danger encountered at work and

proceed directly to withdraw to a safe location. Any employee who discovers any safety issue at work may report it immediately to a plant administrator, nurse, or occupational health and safety officer. There was no record of any personnel disciplined for safety issues reported in 2020.

Occupational health services

LITEON provides pre-employment checkups for new hires as well as regular physical

examinations for active employees. LITEON has installed nurses and emergency care staff in all plants to ensure necessary measures are taken in case of emergency. LITEON hires trained doctors to be stationed in the plants/sites and professional medical assistance for its employees.

In addition, information on the health services, medical assistance and occupational illness prevention provided by the company is given as part of orientation training for new hires.

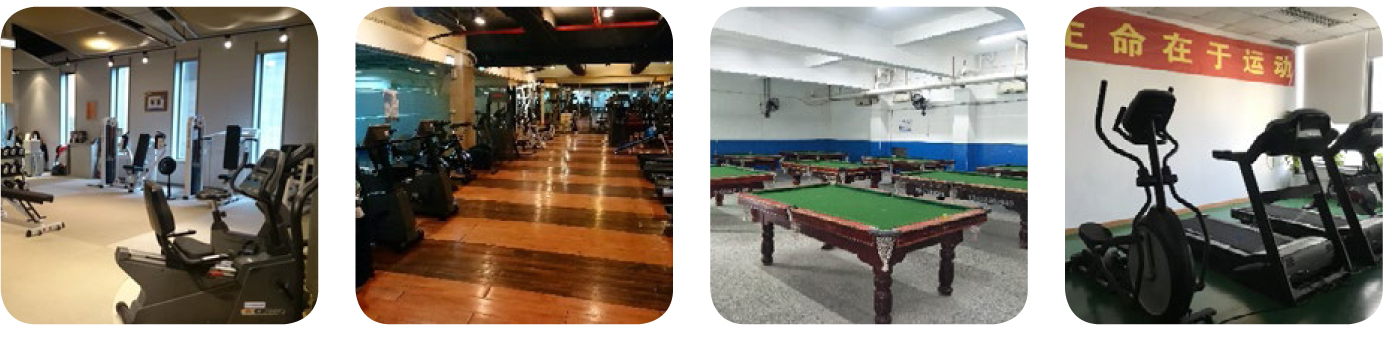

Comfortable working environment

LITEON sets up well equipped fitness centers and libraries for employees as part of a healthy and comfortable work environment. Spacious and comfortable cafeterias not only save employees the trouble of eating out, but allow the company to safeguard food safety for its employees. Friendly onsite services available in the plants include travel agencies and cafes.

Health promotion and a safe working environment

LITEON values a culture of health. The company sends health e-Newsletters from time to time to deliver messages on different topics in order to urge employees to pay attention to their own health. In addition, the company uses articles in the quarterly LITEON Magazine to promote health and safety and prevent hazards as needed. LITEON follows the rules and relevant requirements regarding occupational health and safety training and provides such training to new employees. The company regularly holds health and safety training classes, including classes on electrical safety, the use and management of hazardous chemicals, and first aid. For fire prevention and safety, the company conducts regular fire drills to raise employee awareness of basic fire prevention. All education and training provided by the company is conducted during work hours. Employees will not be penalized by pay reduction or deduction or leave deduction for participating in such training.

Occupational injury and illness prevention

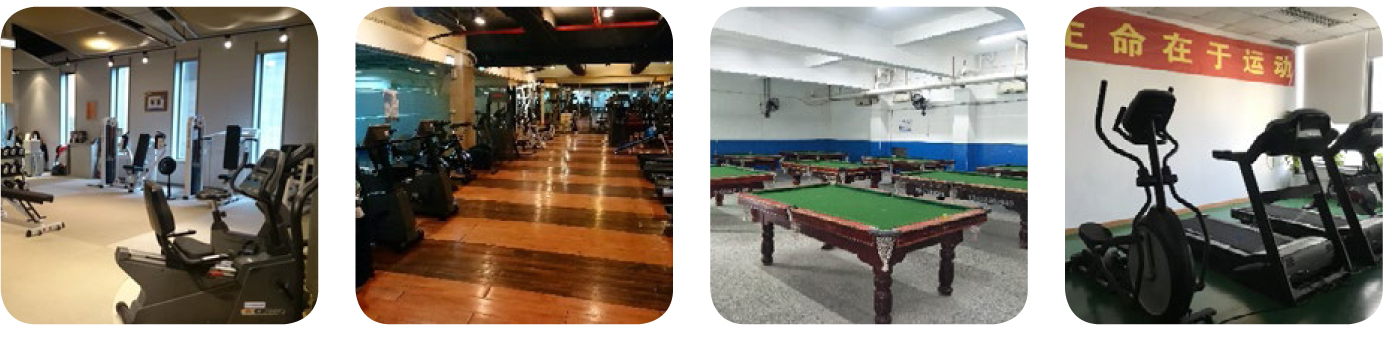

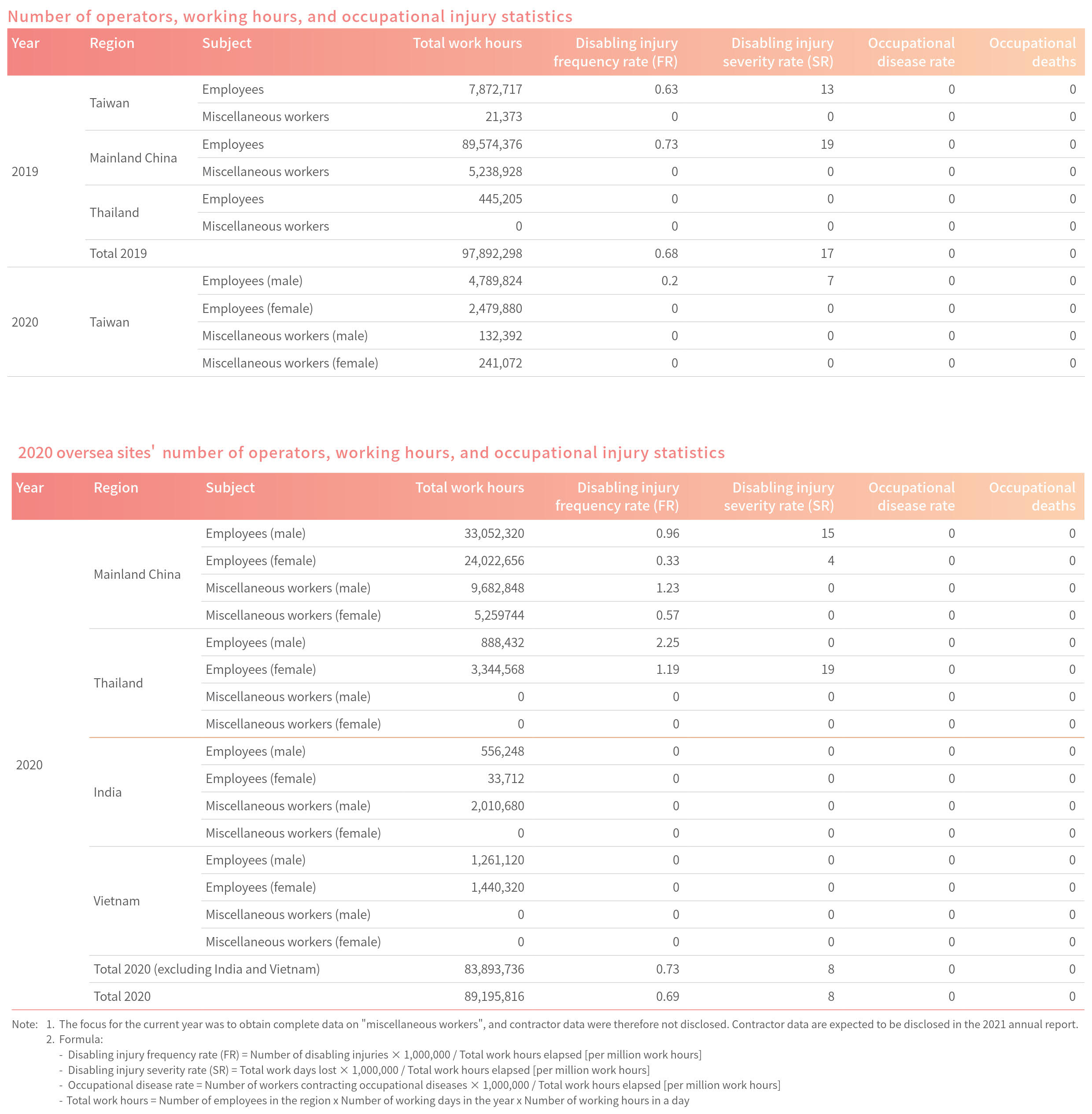

In order to prevent occupational diseases and occupational accidents, all plants have established EHS promotion task forces, which work in conjunction with internal and external audits (consisting of annual environmental, safety, health, and fire safety audits). These task forces oversee environmental health and safety activities throughout the company. A zero workplace accident scorecard is a key operations and management indicator. In accordance with EHS regulations and management systems, LITEON tracks statistics on occupational injuries as follows:

Vietnam and India plants were added to the disclosure for 2020. The global disabling injury

frequency rate was 0.69, and the global disabling injury severity rate was 8.

Before the addition of India and Vietnam plants in 2020, the disabling injury frequency rate was 0.73,

up by 7.3% compared to 2019. The rise was mainly attributed to the 15 cases of work related injuries

in Mainland China in 2020 in addition to those reported in 2019. These injuries were sustained by

miscellaneous workers who were not employed by the company. A total of 60 work hours were lost,

and the injuries were minor. To prevent similar incidents, the company immediately stepped up

health and safety management for miscellaneous workers who were not employed by the company.

The disabling injury severity rate was 8, down by 53% compared to 2019.

Other EHS information please see Occupational safety and health management framwork and measures.

Employee Care ▸

Select Language